Heat transfer

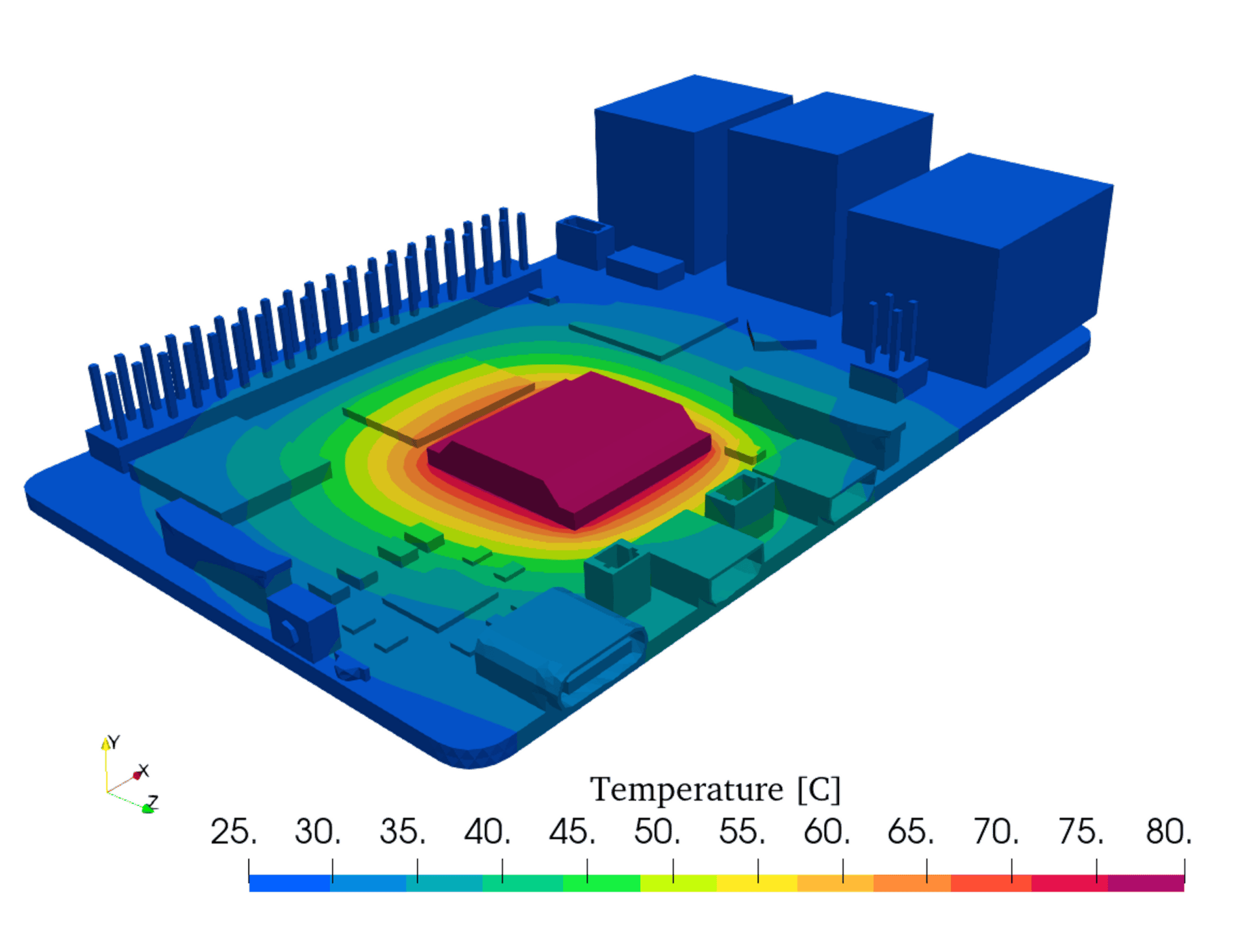

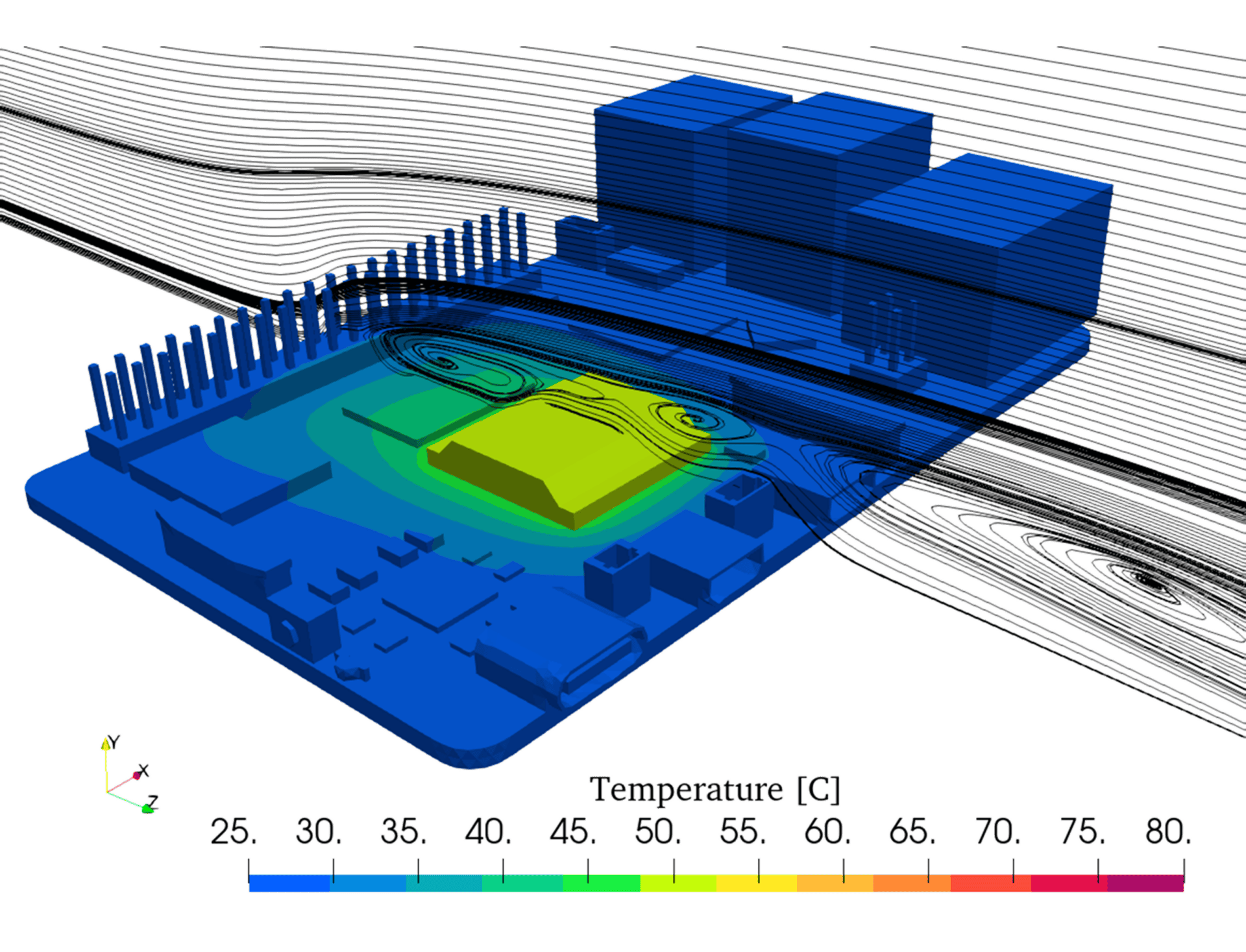

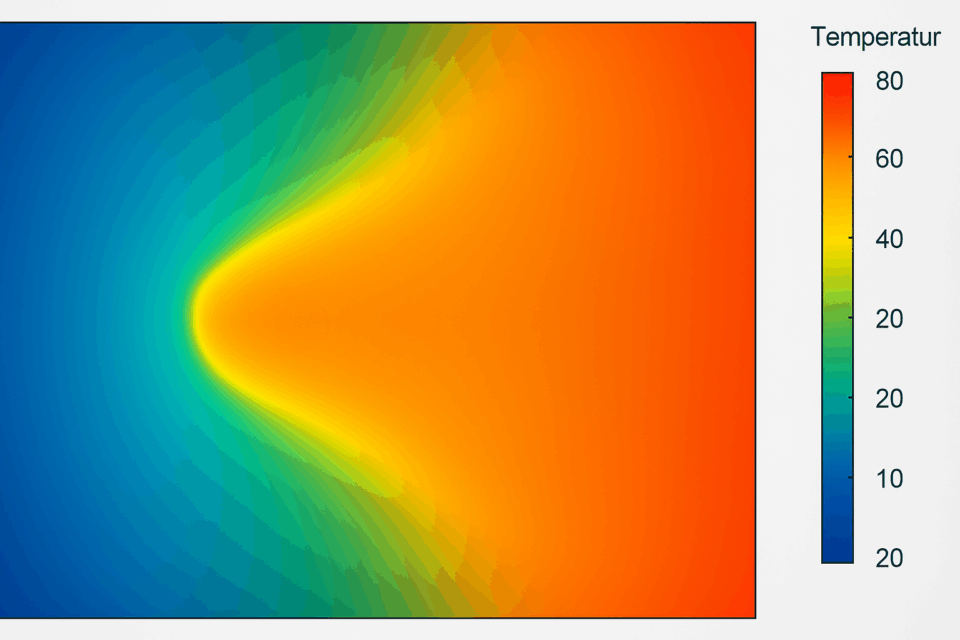

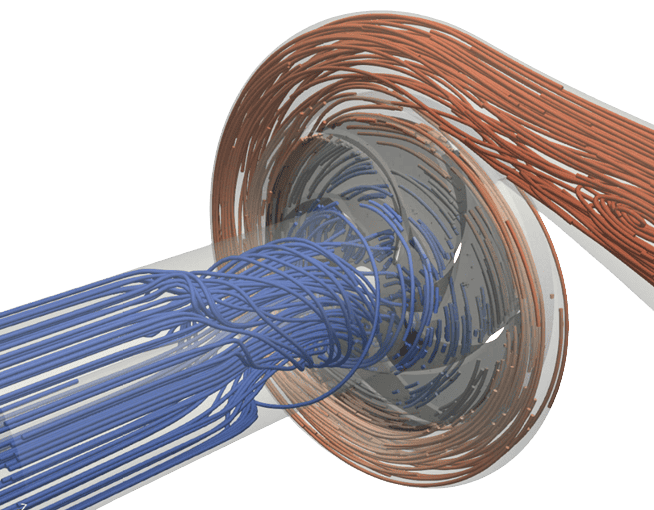

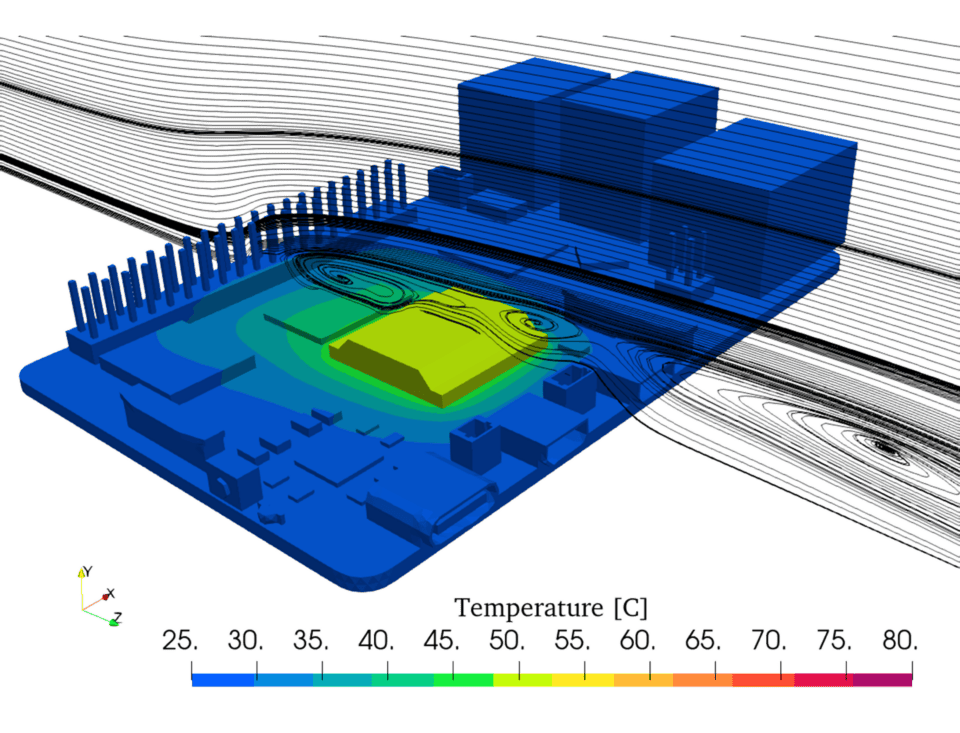

Thermal loads act directly on materials, components and flow systems. Using CFD-supported analyses of heat transfer, we calculate temperature fields, heat flows and hotspots under realistic operating conditions. This allows us to identify critical areas and make targeted improvements.

Heat transfer analysis for components and systems

Efficient cooling, reliable heating

Heat transfer influences the function, efficiency and reliability of numerous components – from electrical components to industrial systems. Unfavorable temperature distributions can reduce performance, damage components or cause entire systems to fail. Conventional calculation approaches are often inadequate for complex geometries or flow-coupled heat flows.

Using CFD-supported heat transfer analyses, we calculate stationary and transient temperature fields, model free and forced convection and take heat conduction into account. This enables us to identify hotspots, inefficient systems and thermally critical areas at an early stage of development.

Typical applications range from electronics cooling, heat exchangers and machine components to large industrial plants or room airflows.

Our range of services

Heat transfer

We create CFD-based analyses of heat transfer in parts, components and systems - precise, comprehensible and directly usable for construction, design optimization and operation.

Learn more

Learn moreTemperature distribution

CFD simulations can be used to realistically map the heating and cooling behavior of their flows.

Learn more

Learn moreSpeed distribution

We analyze flows in your systems - precisely, comprehensibly and with clear findings on dead zones and bypasses.

Flow optimization

Increased efficiency and improved performance of your systems through targeted optimization of the flow based on suggestions from our experts.

A heat transfer analysis is worthwhile if ...

Your challenges - our solutions

you want to detect and avoid critical temperature zones in components, machines or systems at an early stage.

you need to develop, improve or verify cooling or heating concepts.

you want to thermally optimize performance-relevant components - e.g. electronics, battery systems, tools, motors or heat exchangers.

You want to model flow-coupled processes such as free or forced convection realistically.

you want to compare material alternatives, geometry variants or operating conditions without producing physical prototypes.

you need a well-founded basis for decision-making on design, safety or service life assessment.

Advantages of heat transfer analysis

Measurable benefits. Verifiable quality

An analysis of the heat transfer provides reliable data on temperature distributions, heat flows and critical component areas - the basis for safe and economical systems.

Early detection of thermal risks

Hotspots, uneven heating and overloaded components become visible and can be remedied by design.

Improved efficiency & service life

Optimized heat conduction, improved cooling concepts and suitable materials increase reliability and extend service life.

Realistic mapping of complex heating processes

Combined simulation of convection, conduction and, if necessary, radiation enables precise evaluation of real operating conditions.

Our expertise for your project

We look forward to your inquiry!

We support you in all areas of heat transfer – from CFD modelling and simulation to the derivation of specific thermal optimization measures.

Do you have any questions, need an assessment or want to get started right away?

We look forward to hearing from you – by phone, email or in person.

Your contact person: Jonas Compart

elbcore engineers GmbH

Lerchenstraße 28a

22767 Hamburg

Strong across all sectors

Our services are used throughout the industry

Our engineering services are used in a wide range of industries - wherever safety, efficiency and technical precision are required.

Plant & tank construction

Electrical engineering

Mechanical engineering

Metal / steel construction

Shipbuilding

Special machine construction

Valve & pump technology

Your sector not listed?

Now contacted

Do you have an exciting project?

Tell us about it.

Arrange a consultation now or send us a project inquiry.

Frequently asked questions about heat transfer (FAQ)

Quick answers. Clear solutions.

Here you will find answers to the most frequently asked questions about our services.

Which applications can be investigated with regard to heat transfer?

We analyze electronic assemblies, machine components, heat exchangers, batteries, cooling concepts, industrial furnaces, process systems, tool temperature control, flow channels and much more. If your system or process is not listed, please do not hesitate to contact us.

What data is needed to analyze heat transfer?

Typically, we need a 3D model of the system or section to be inspected. We will discuss everything else with you in a short and free web appointment (NADJA: link here to the consultation appointment). Other typical data required are data sheets of e.g. fans or heaters, material distributions and boundary conditions of the processes, e.g. starting temperature.

What references does elbcore engineers GmbH have in the field of heat transfer?

Our references in heat transfer range from electronics cooling (e.g. pumps, circuit boards) for clean room applications to cooling concepts for machine rooms, systems and data centers to time-dependent heat exchanger calculations. We also regularly optimize machines in order to improve heat dissipation.

Do you still have questions? We are here for you.

Contact us now