Transportation places considerable mechanical stress on components and products. Vibrations, shocks and impacts affect materials and structures long before they reach their place of use. Especially in industrial supply chains where sensitive components, complex assemblies or difficult-to-transport devices are moved, the reliable prediction of such stresses is crucial. Virtual transport simulations enable these loads to be simulated realistically – precisely, reproducibly and without cost-intensive physical test series.

Critical stresses, deformations and vibrations can already be determined in the development phase using physically correct models, e.g. in accordance with IEC standards such as DIN EN IEC 60721 and excitation profiles based on measurement data. In this way, components and packaging can be designed to withstand the actual transport loads and functional safety can be guaranteed even after transportation.

Simulation of real transportation environments

A transport simulation maps the various phases of the flow of goods – from internal handling and road transport to air and sea freight. It is based on defined

Each simulation is based on a sequence of loads that act on the component or packaging one after the other. These include drop tests from defined heights, compressions caused by stacking loads and, in particular, stochastic vibration excitations, such as those that occur during truck or rail transportation. The load-time curves are described using specific power density spectra (PSD), which reflect the actual vibration intensities from field measurements.

By coupling this input data with a detailed FEA model, local stresses and deformations in the component can be calculated. Based on these results, it becomes clear whether a structure remains stable even under dynamic influences or whether there are critical weak points.

Random vibration and dynamic tests

A central component of the transport simulation is the random vibration analysis, in which the behavior of the component is examined under randomly distributed vibration excitations. In contrast to sinusoidal vibrations, which only excite a single frequency, the random method maps the entire frequency spectrum of real transport vibrations.

For the calculation, power density spectral excitations are applied to defined contact surfaces or bearing points of the model. This makes it possible to see how dynamic energy is distributed over the frequency range and which natural frequencies lead to increased stresses. This method allows a realistic assessment of the load during a complete transport – especially for components that are exposed to uniform vibrations over long periods of time, such as truck or rail transports.

The use of non-linear material models and contact-based couplings within the FEA simulation ensures that deformations, damping effects and plastic reserves are physically correctly taken into account. In this way, microcracks, loosening or resonance damage can already be detected in the virtual prototype and avoided in the design.

Vertical vibration testing of complete packages

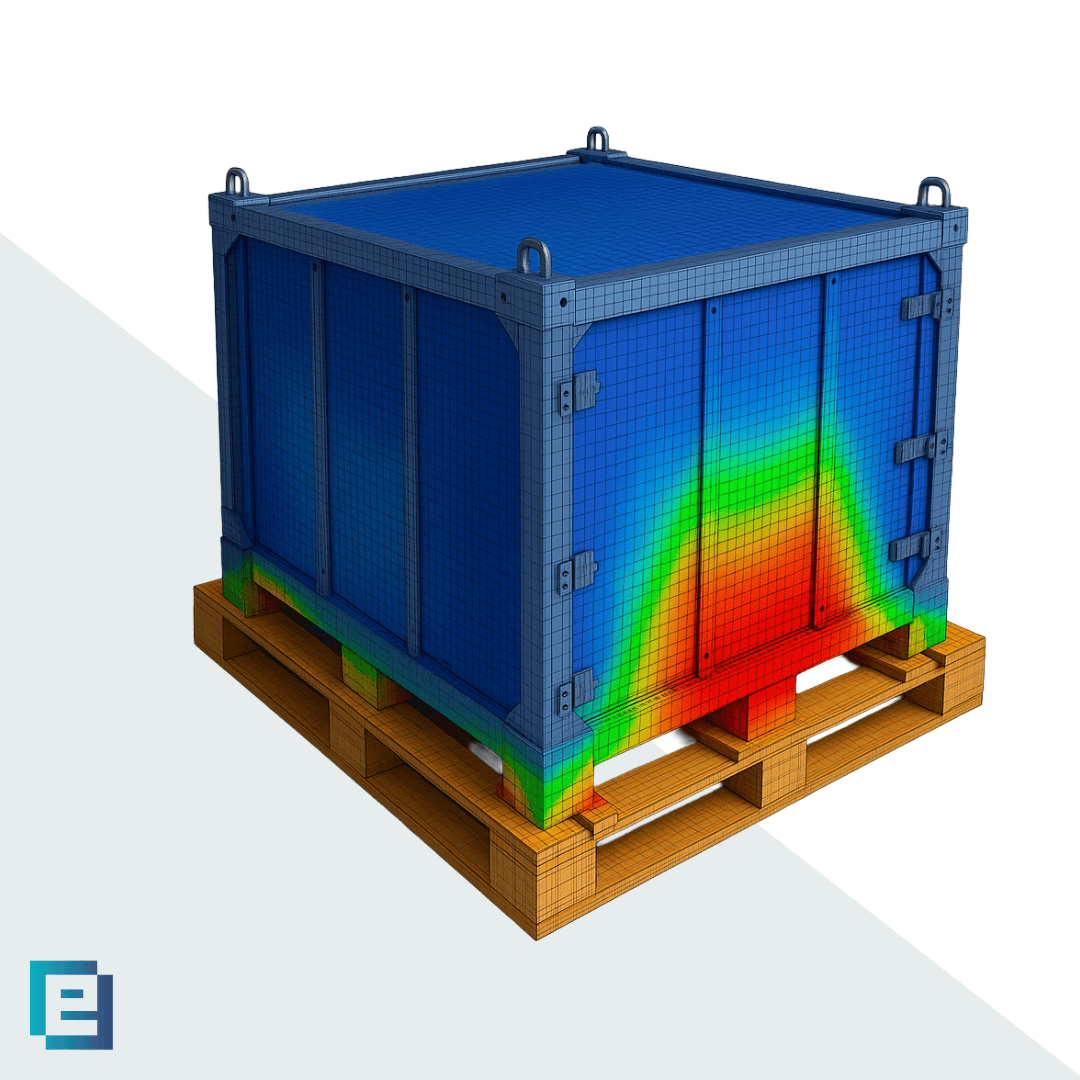

In addition to the simulation of individual components, the investigation of complete transport packaging and unit shipments plays a central role. The systems are subjected to vertical random vibration profiles that map characteristic acceleration levels and frequency spectra.

The aim is to evaluate the protective effect of the packaging and the structural integrity of the product within the overall system. By numerically simulating the load over the entire frequency range, it is possible to check whether the packaging system dampens vibrations sufficiently or whether excessive load peaks are transferred to the product.

This aspect is particularly relevant in branches of industry such as mechanical and plant engineering, energy or container construction. Large components or aggregates, which are often transported as a unit on pallets or racks, are subject to a large number of vibrations that can be reliably mapped in the simulation.

From virtual test to safe product

Our simulations enable damage and failures to be detected and avoided at an early stage. All transport phases can be mapped digitally and the design can be specifically adapted to the loads that actually occur. In addition, optimization potential is opened up – for example by adjusting wall thicknesses, struts or holding points.

The results obtained serve as proof that a product can withstand the mechanical effects during transportation without suffering unacceptable deformation or loss of function.

Conclusion

Virtual transport simulations combine practical load scenarios with the precision of modern FEA analyses. They form the basis for preparing products for transportation safely, efficiently and in accordance with standards – regardless of whether they are transported by road, rail, sea or air. In combination with guidelines for strength assessment, such as the FKM guideline or VDI 2230, binding statements can be made about the strength of your components.

If damage occurs to your systems during transport, targeted optimizations can be developed to prevent this. Please contact us for a free, no-obligation consultation.