An excerpt from our everyday work – simulation instead of standstill: fatigue analysis on a storage and retrieval machine

Storage and retrieval machines are the heart of modern high-bay warehouses. They move at high speed through narrow aisles, lift and lower loads several dozen meters high and have to guarantee maximum precision at all times. The dynamic nature of these systems means that the structures used are exposed to considerable alternating loads. If damage occurs to load-bearing components, the result is not only repair costs but also expensive production downtime.

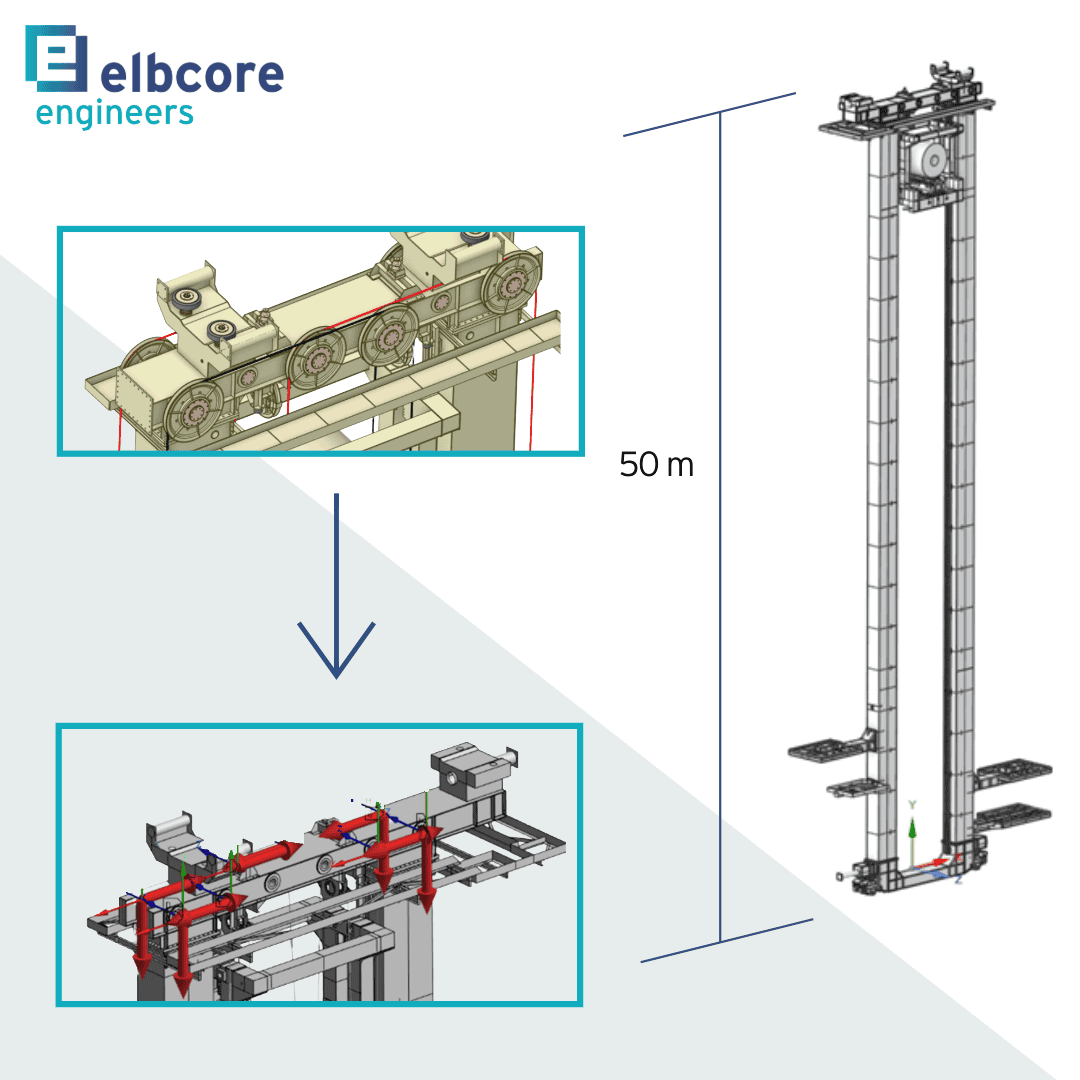

In a recent project, we were faced with precisely this challenge: damage had become visible on the head beam of a storage and retrieval unit. Cracks indicated that this was a classic fatigue problem – a consequence of recurring loads that stress the material over long periods of time. A key question arose for the operator: should the affected storage and retrieval machine with a height of around 50 meters be completely replaced – involving high investments and longer downtimes – or could an equally safe but significantly more economical solution be achieved through targeted repair measures?

Realistic simulation as the key

It was only possible to answer this question if the actual operating conditions of the appliance could be precisely reproduced. This is because only a realistic depiction of the load scenarios allows the cause of the damage to be identified and the service life to be correctly estimated.

One particular challenge was that no current design data for the appliance was available. Instead, we had to build the calculation model on the basis of existing old drawings and repair measures that had already been carried out. These were carefully digitized and converted into a numerical model so that all relevant geometries were captured. This created the basis for mapping the real operating data in an FEA analysis.

We then analyzed the load data recorded during operation in detail and fed it into the model. Finite element analysis (FEA) was used to simulate all relevant load conditions – from acceleration and deceleration processes to alternating lifting movements. This resulted in a complete picture of the stress situation in the head crossbeam.

It was particularly important not only to use idealized load assumptions, but also the actual load collectives. This was the only way to ensure that the simulation corresponded to the real operating conditions.

Evaluation according to FKM guideline

The FKM guideline “Calculated proof of strength for machine components” was used for the subsequent assessment of fatigue safety. This has been established for many years as the standard in mechanical engineering when it comes to calculating fatigue strength and predicting service life under real load collectives.

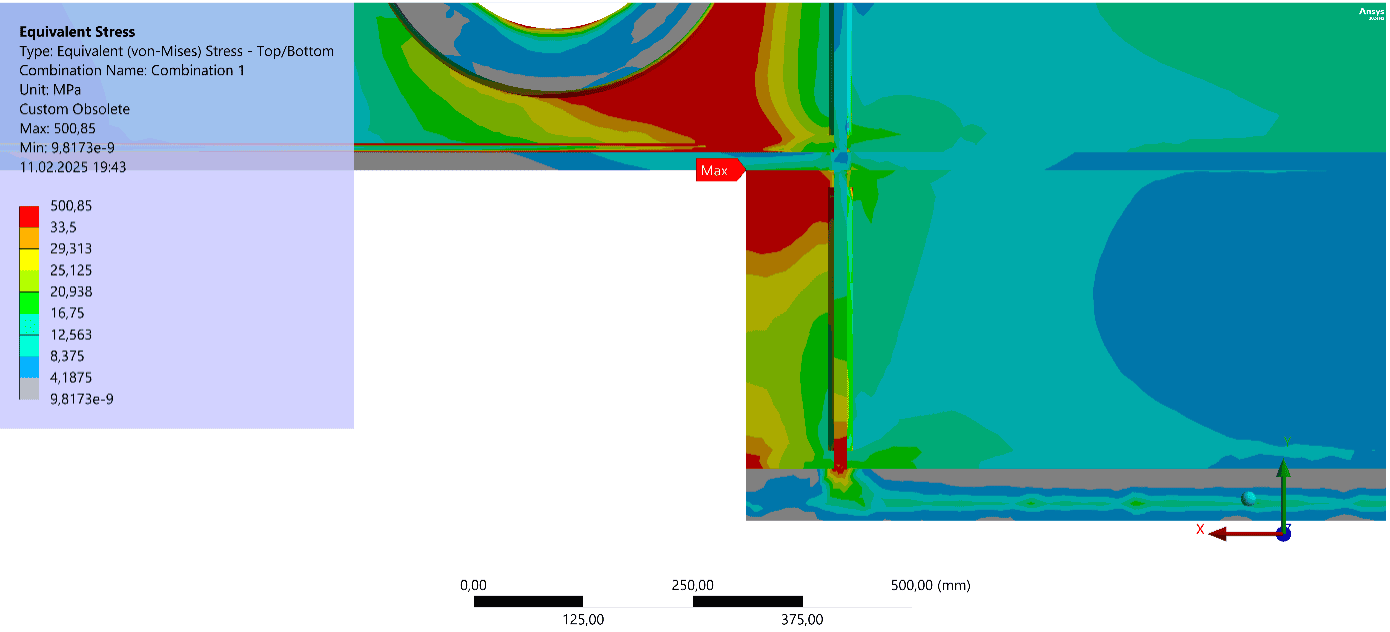

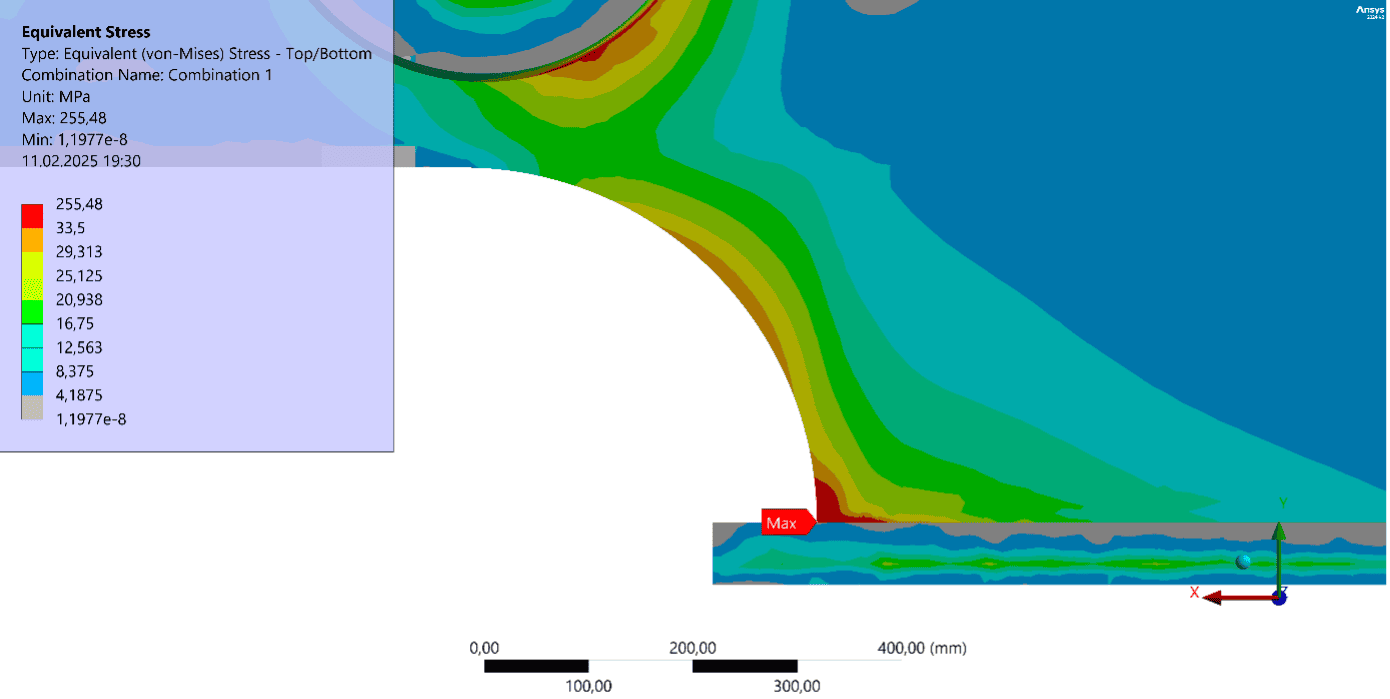

The FKM guideline offers the advantage that it provides a systematic and comprehensible procedure for the verification of fatigue strength. On this basis, we were able to quantify the critical areas in the head crossbeam and assess their remaining service life. This made it possible to classify the damage that had already occurred and to estimate the effects on future operational safety.

Results: Simulation and reality in harmony

The evaluation provided a clear insight: the calculated high-stress areas corresponded exactly with the damage points that occurred in reality. This proved that the cracks that occurred were not random, but a direct result of the operational load spectra.

This correspondence between model and reality is a decisive advantage of modern simulation technology. It creates confidence in the results and makes it possible to make statements about the future development of damage with a high degree of certainty.

In addition, we were able to predict the fatigue life of the affected areas based on the FKM calculations. This made it possible to assess the risk of progressive damage and derive well-founded recommendations for action.

Repair instead of replacement – the economical solution

Based on the analysis and assessment in accordance with the FKM guideline, we developed various measures to strengthen the head beam. The aim was to reinforce the highly stressed areas in such a way that further cracking is stopped and safe continued use is possible.

The implementation of these measures by the operator had several advantages:

- Avoiding a cost-intensive replacement: A complete replacement of the crossbeam would not only have resulted in high material and assembly costs, but also a longer interruption to warehouse operations.

- Minimization of downtimes: Targeted repair and reinforcement meant that the device could be put back into operation much more quickly.

- Ensuring operational safety: the measures increased the service life and reduced the risk of further damage

Conclusion: Added value through simulation according to recognized standards

The project is an example of the added value that numerical simulations offer in everyday industrial life. They are not only a tool for the development of new products, but also a crucial component in the evaluation and maintenance of existing systems.

Particularly in the case of dynamically loaded systems such as storage and retrieval machines, FEA allows critical areas to be precisely identified and their future development to be predicted. The application of the FKM guideline ensures that the evaluation is based on a recognized engineering standard – comprehensible, practical and verified.

For operators, this means well-founded decisions instead of costly uncertainties. Whether replacement, reinforcement or repair – the analysis provides the basis for the economically and technically optimal solution.

Outlook

The procedure of integrating real operating data into the simulation and evaluating it in accordance with the FKM guideline can be transferred to many other applications – whether in conveyor technology, mechanical engineering or energy supply. Wherever components are subjected to cyclical loads, modern fatigue analysis methods can be used to identify critical areas and initiate measures in good time.

This makes it clear that simulation according to the FKM standard is a key tool for predictive maintenance. It makes the difference between costly downtime and the safe, efficient continued use of existing systems.

If you are also faced with the decision of whether to replace or repair components, we support you with practical simulations and assessments in accordance with the FKM guideline. This gives you a reliable basis for making economically and technically optimal decisions – before cost-intensive failures occur.

👉 Please feel free to contact us to find out more about our services in the areas of FEA, fatigue analysis and service life prediction. Together we will find the right solution for your challenge.