Virtual shock calculations are indispensable in the defense industry – especially for the navy. They enable the realistic simulation of extreme loads caused by explosions or shock pulses where physical tests reach their limits. By using the Finite Element Analysis (FEA), plastic load reserves, bolt verifications in accordance with VDI 2230 and complex load cases can be precisely investigated. This increases the safety of systems, minimizes development risks and strengthens competitiveness.

Importance of shock calculation in the defense environment

The defense industry places exceptionally high demands on the resilience of components and systems. Whether armored vehicles, naval platforms or electronic assemblies – shock events caused by explosions, ballistic impacts or hard transport and operating loads are a key issue. Shock loads caused by underwater explosions pose an extreme challenge, particularly in the maritime environment, for example in the use of ships and submarines. Shock calculation plays a key role for the navy here, as the evidence is directly linked to operational safety.

Traditional test methods quickly reach their limits with these tasks: they are cost-intensive, logistically complex and often difficult to reproduce. Virtual shock calculations based on the Finite Element Analysis (FEA) make it possible to overcome these challenges precisely, efficiently and economically.

Methodological approach: From linear to non-linear

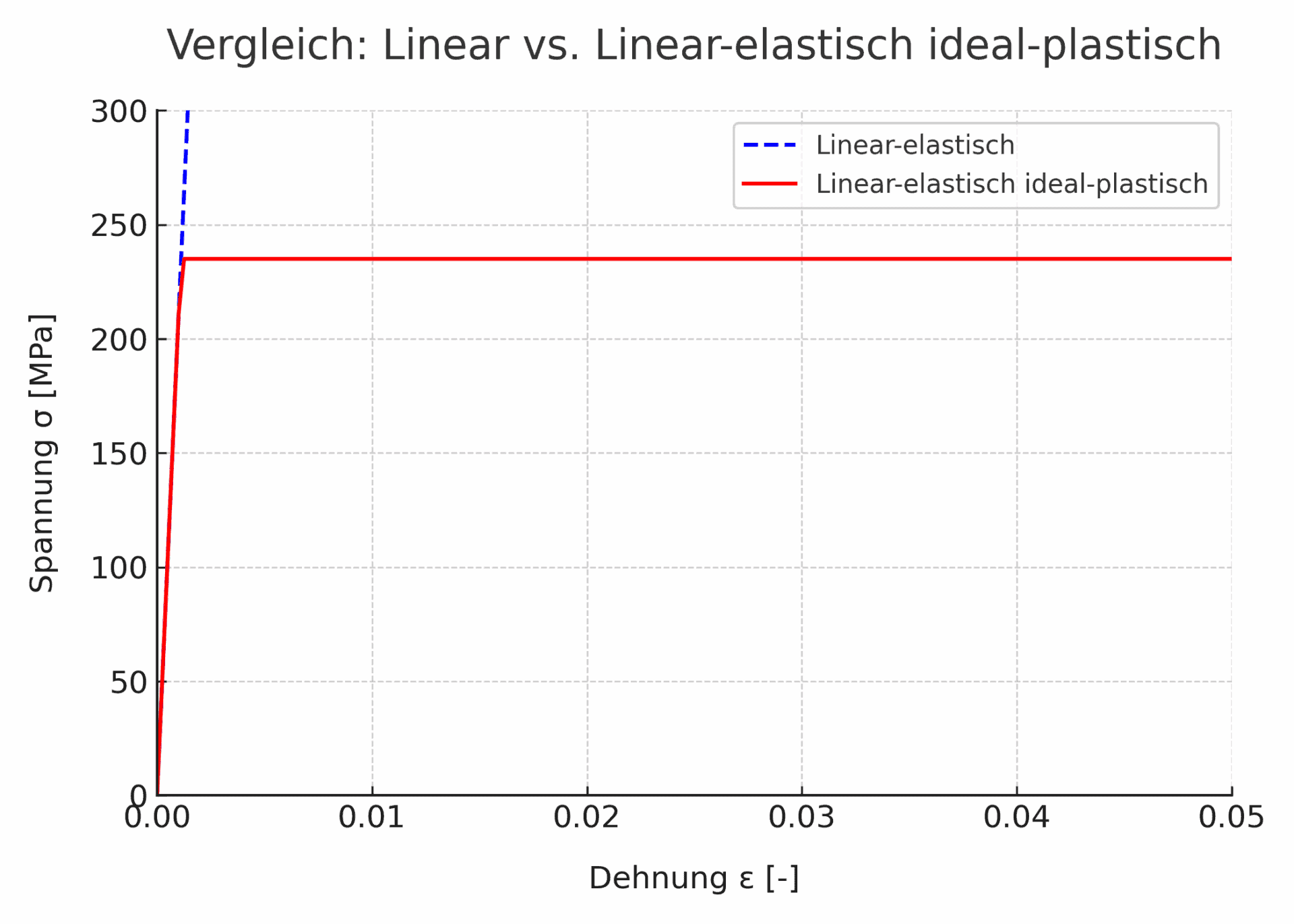

A decisive advantage of the FEA-based shock calculation lies in the differentiated mapping of the material behavior. While simple linear models provide initial estimates, they only reflect reality to a limited extent. Particularly in the defense industry and especially in the marine industry, where components are stressed to their limits, the consideration of plastic load-bearing reserves is essential.

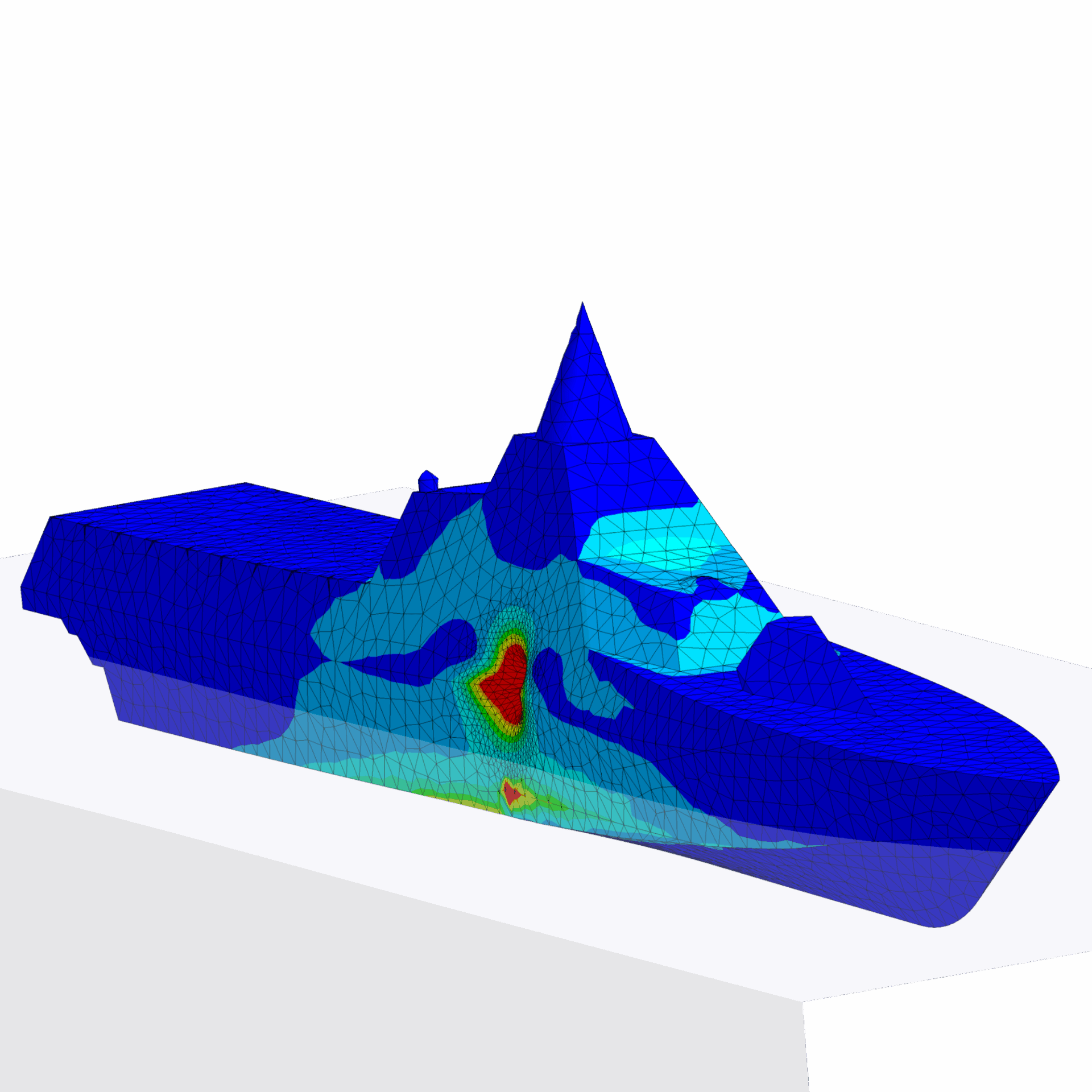

Figure 1 shows the comparison of a purely linear elastic material model with a linear elastic ideal plastic (non-linear) model. By using non-linear material laws, permanent deformations, energy absorption mechanisms and failure modes can be reliably predicted. Depending on the problem at hand, the analysis can be transient, i.e. time-dependent – for example, to investigate the progression of a load over time. This flexibility makes the method an indispensable tool in the defense environment.

Sequence of a virtual shock calculation

The path from the problem definition to the reliable result follows a clearly structured process. The starting point is the definition of load cases. Engineers refer to standards, customer specifications or realistic application scenarios. In shock calculations for the navy, for example, this includes pressure curves from underwater explosions or shock pulses that affect ship hulls and sensitive systems.

The numerical model is then created. A suitable FEA model depicts both the geometry and the relevant interfaces, such as screw connections or bearings, in a practical manner. The quality of the meshing plays a central role here, as it significantly influences the accuracy of the results. At the same time, contacts between components must be defined realistically, as they are crucial under shock load.

The material properties are determined at the same time. In addition to linear characteristic values, it is precisely the non-linear properties that are indispensable in the field of shock calculation for the navy and in the defense industry. They make it possible to realistically evaluate the load-bearing reserves beyond the elastic range.

The actual calculation is then carried out depending on the scenario. Transient analyses are particularly relevant for maritime applications, as the dynamics of underwater shocks can only be realistically mapped as a function of time. Quasi-static approaches, on the other hand, are suitable when the focus is on end states or limit loads.

The simulation is followed by a detailed evaluation. Our engineers analyze stresses, strains and deformations and identify critical weak points. In addition, specific verifications, such as the bolt verification in accordance with VDI 2230, can be provided in order to safeguard fasteners under extreme loads.

Advantages of virtual shock calculation

The shock calculation shows its strengths particularly with large structures or components that are difficult to access, as is often the case in the navy. Physical tests can only be carried out to a limited extent here. Simulations, on the other hand, make it possible to run through various scenarios flexibly and reproducibly – from underwater detonations to shock pulses on complex ship systems.

The advantages are manifold: high flexibility in the investigation of different load cases, transparent insights into component behavior and the ability to significantly shorten development cycles. Risks can be identified at an early stage, weak points can be specifically addressed and both costs and time can be saved.

Role of the FEA model for reliable results

The quality of a shock calculation depends crucially on the quality of the FEA model. Practical meshing, precise mapping of relevant contact points and consideration of non-linear material laws are essential. Experience shows that careful modeling not only increases accuracy, but also reduces project costs, as fewer iterations are necessary. For our customers, this means reliable results and efficient project management.

Conclusion – Safety through simulation

Shock calculation in the defense industry is a key instrument for verifying the safety and reliability of components. Shock calculation is particularly indispensable for the navy, as extreme loads occur here that can hardly be reproduced in real tests. Virtual methods offer a practical and reliable alternative to experimental tests, which alone are not sufficient. Companies that use simulation to validate their systems at an early stage reduce risks, accelerate development and secure their competitiveness.

If you need support with the shock calculation for your project – whether in the maritime environment or in other areas of the defense industry – we will be happy to assist you with our expertise.