Weld seam calculation and

-Design

You can rely on precise weld seam calculations. The design is carried out with a view to safety, service life and cost-effectiveness – tailored to your requirements.

Long-lasting safety for your weld seams

Mastering loads. Design connections safely.

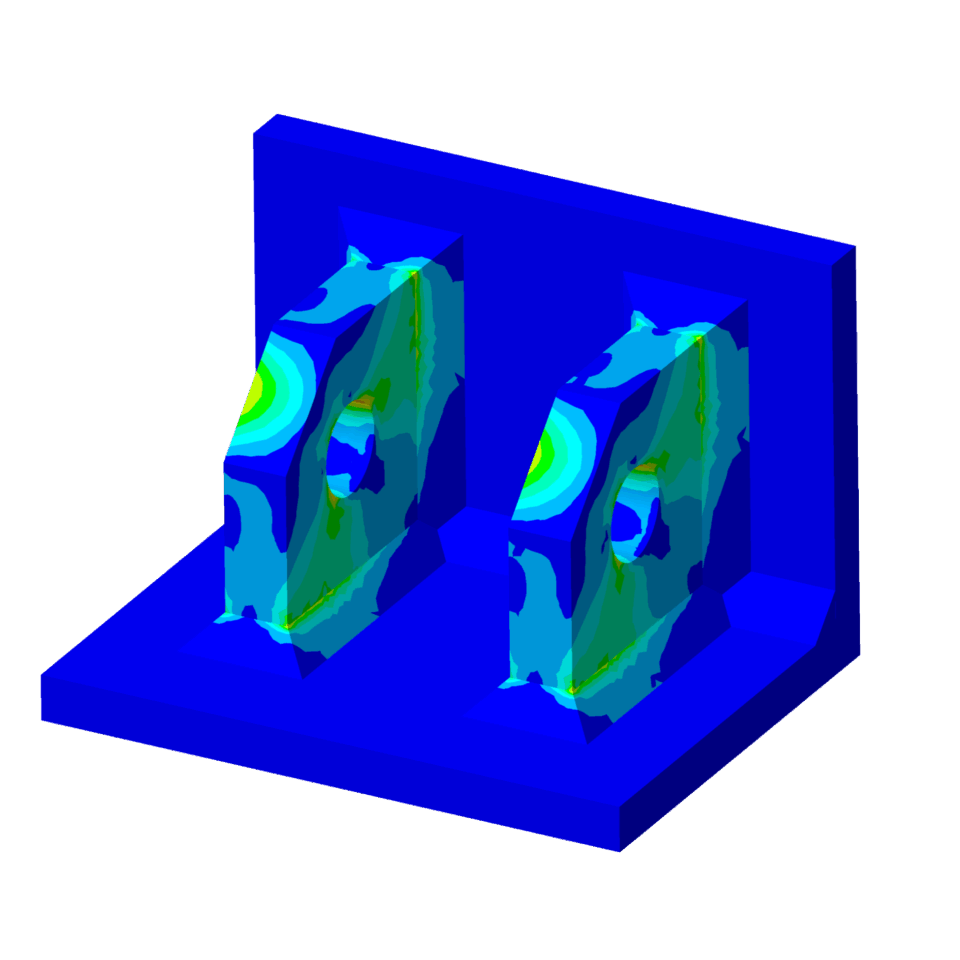

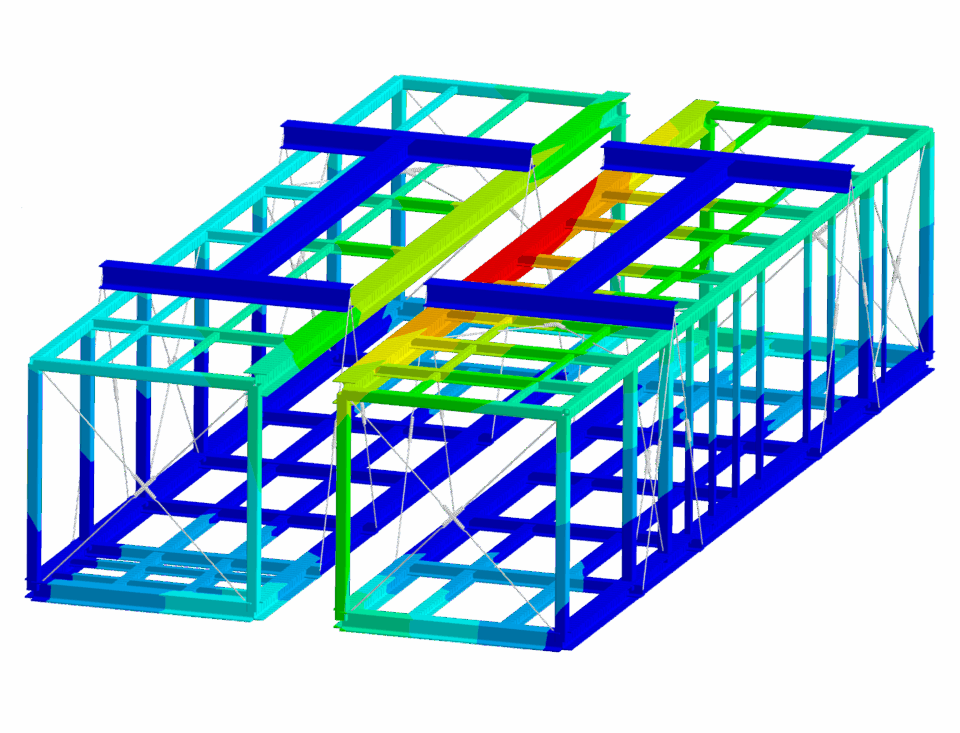

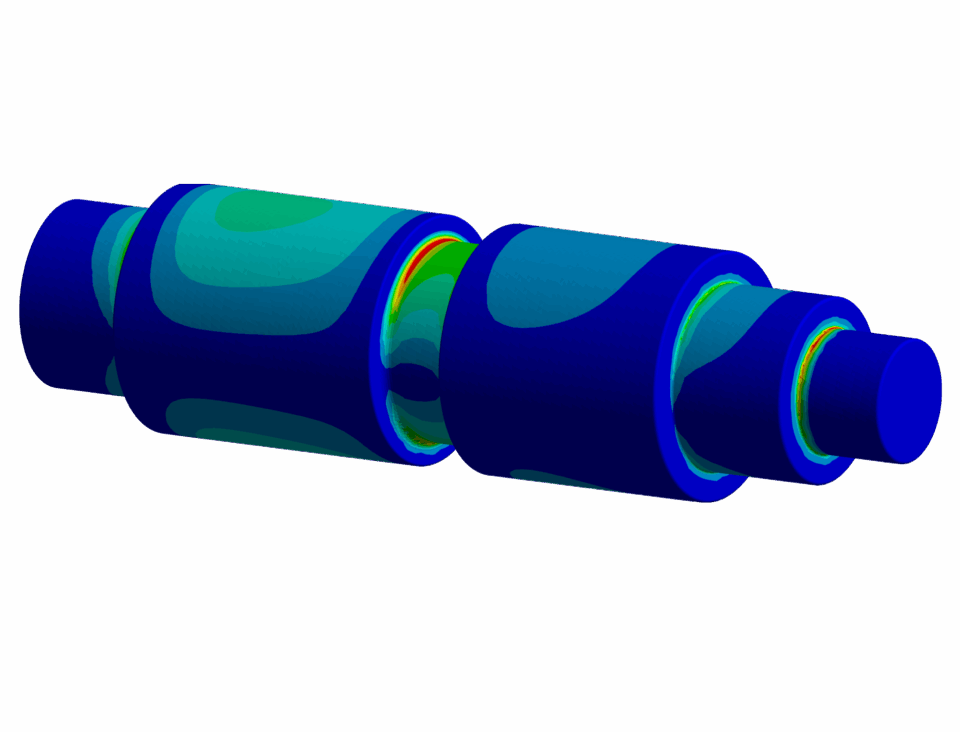

Proof of the strength of welded joints is crucial for the reliable design of load-bearing structures – whether in mechanical and plant engineering, automotive engineering or steel construction. Both static peak loads and cyclical stresses caused by recurring forces or thermal influences can have a decisive influence on the service life.

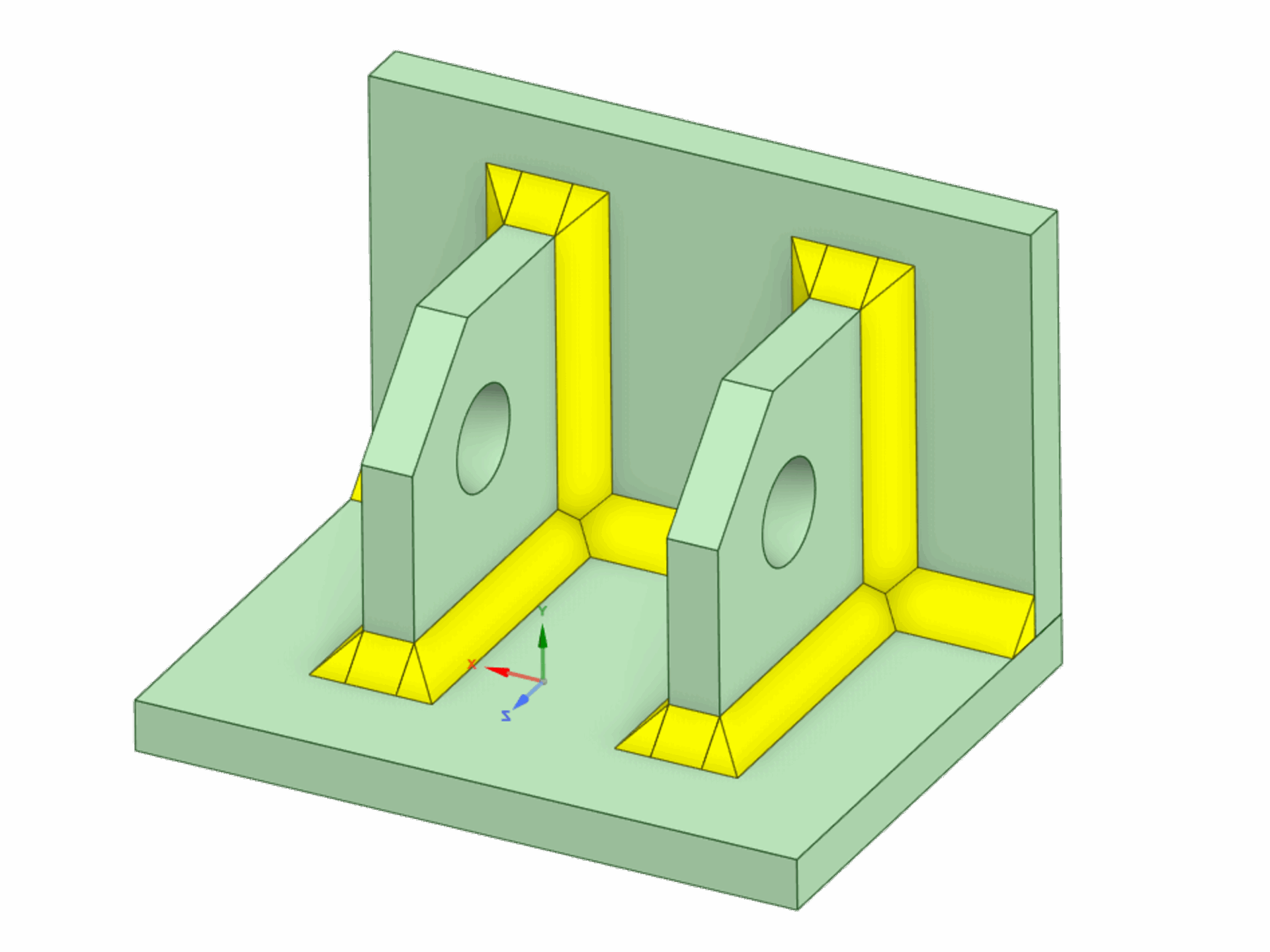

The calculation takes into account geometry, stress curves and seam designs – in accordance with standards, e.g. the FKM guideline or on the basis of experimental characteristic values. The aim is to identify weak points at an early stage and to ensure the load-bearing capacity of your welded joints in the long term.

Weld seam verifications are essential when ...

Your safety - our responsibility

structural weld seams are located in highly stressed areas - for example in the force flow - and must be evaluated as potential weak points.

load-bearing welded joints are subject to cyclic loading and proof of fatigue strength is required.

failure due to cracking under real operating conditions is to be avoided - especially in the case of safety-relevant components.

the design is to be economically optimized in terms of material use, seam shape and production without compromising safety.

the stress and deformation behavior of the welded joint is decisive for the overall function of the structure.

Advantages of weld seam calculations

Measurable benefits. Verifiable quality.

With virtual simulations and sound calculations, we support you in developing products faster, safer and more economically. Our claim: reliable results that you can rely on.

Prevention of component failure

A strength verification of the weld seams can be used to ensure that the component can withstand the loads acting on it. This protects people and property.

Dimensioning of weld seams

We determine the required dimensions of the weld seams to ensure a safe and resilient component. Especially with cyclical loads, it is difficult to estimate in advance.

Optimization of weld seams

If thick sheets are part of your design, optimizing the a-dimension can often significantly reduce the welding effort and therefore your costs.

Our expertise for your project

We look forward to your inquiry!

As a specialized engineering office for FEA calculations and simulations, we offer you sound technical support in the design and evaluation of weld seams. Whether static or cyclic loads – we check whether your machine or construction can withstand the loads.

Do you have questions, need an assessment or want to get started right away?

We look forward to hearing from you – by phone, e-mail or in person.

Your contact person: Jonas Compart

elbcore engineers GmbH

Lerchenstraße 28a

22767 Hamburg

Do you have an exciting project?

Tell us about it.

Arrange a consultation now or send us a project inquiry.

Frequently asked questions (FAQ)

Quick answers. Clear solutions.

Here you will find answers to the most frequently asked questions about our services.

Which standards can be used for the strength verification of weld seams?

We carry out weld seam verifications in accordance with the FKM guideline, DIN EN 1993 and other industry-specific standards. Customer-specific requirements or international standards (e.g. AD2000, DIN EN 13445) can also be taken into account. Please contact us if your standard is not listed!

Can weld seams be reliably verified in a FEA simulation?

Yes, modern FEA simulations enable realistic stress analysis on and in the vicinity of weld seams. However, suitable evaluation methods must be used for standard-compliant verification – such as structural stress approaches, notch stress concepts or hot-spot methods. We combine FEA results with proven verification methods in order to provide reliable and verifiable statements on weld seam strength.

What information do you need to carry out a weld seam verification?

For a weld seam verification, we require design data, material characteristics, load specifications and information on the welding process. Subsequent assessments are also possible. Contact us – we will be happy to examine your application in detail.

Do you still have questions? We are here for you.

Contact us nowDiscover more services

ELBCORE ENGINEERS GMBH

Discover other services with which we support your product development in a targeted, efficient and standard-compliant manner - from specialized simulations and comprehensive strength verifications to individually automated calculation processes.

Static strength verification

A static strength verification checks whether a component can withstand the intended loads permanently and safely.

Fatigue strength verification

Fatigue describes the gradual failure of components under repeated, cyclical load.

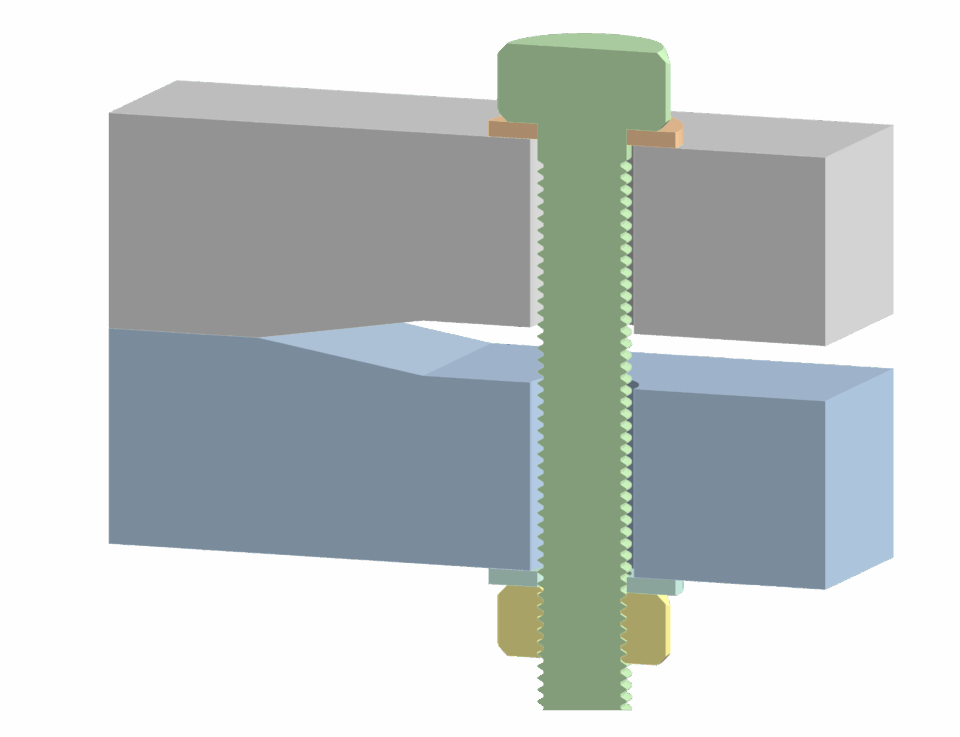

Screw calculation

Bolt verifications check the load-bearing capacity of prestressed and non-prestressed connections - depending on the type of load.