Static strength verification

Safety that lasts. The static strength verification shows at an early stage whether your component will hold up mechanically – transparently, economically and in accordance with standards.

Binding evaluations of your components

Static safety right from the start

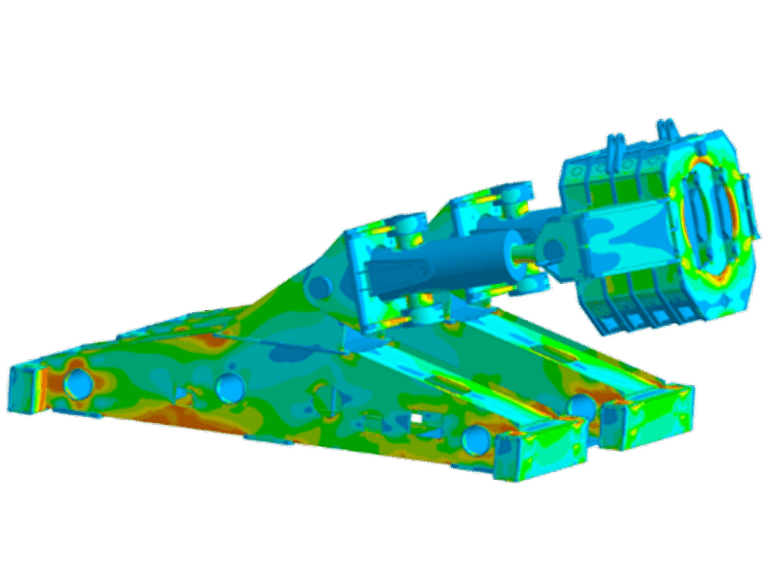

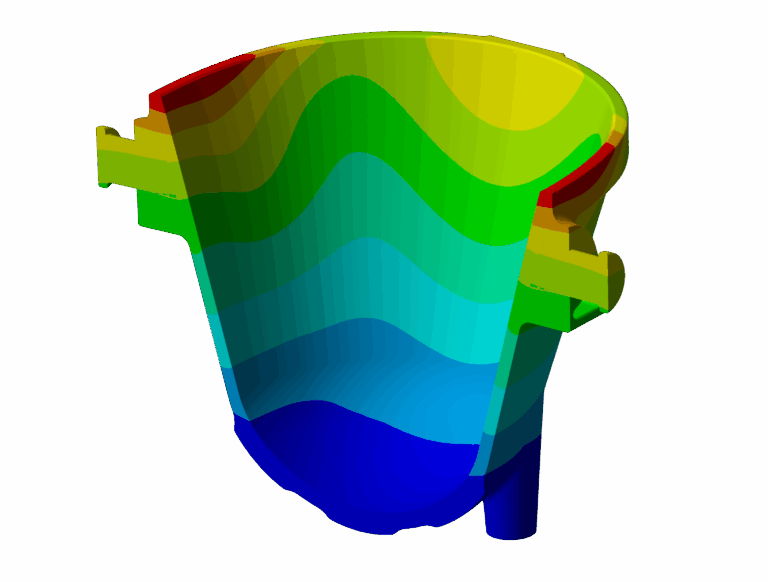

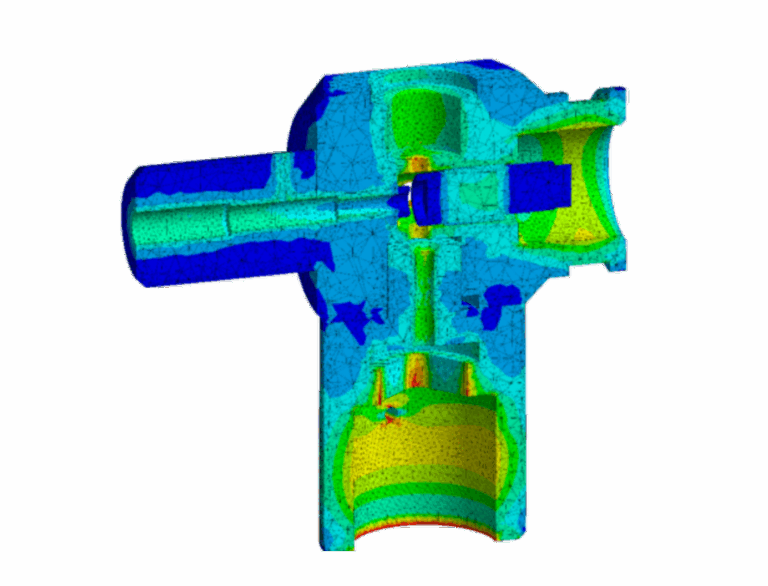

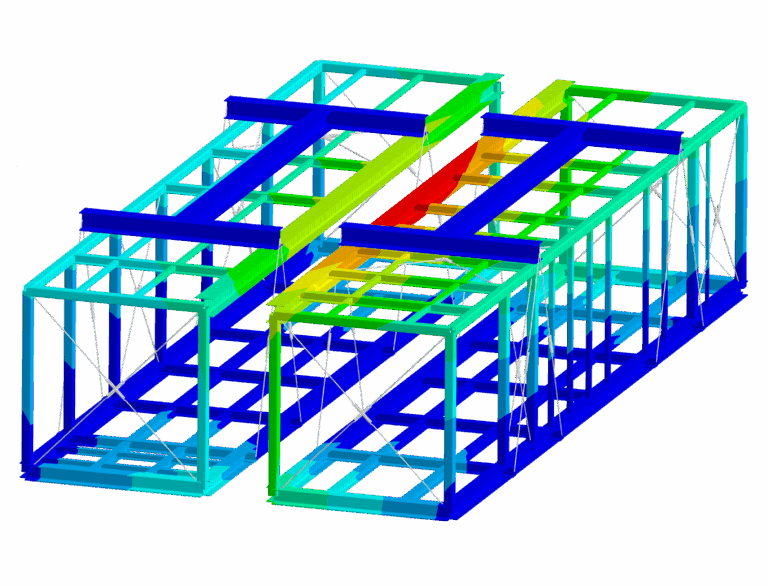

A static strength verification is a procedure in engineering, particularly in mechanical engineering and civil engineering, to check the load-bearing capacity and safety of your structure or component under static load. Static loads are forces or moments that act constantly or only slowly changing on a component in contrast to dynamic or alternating loads.

The static strength calculation ensures that your component can withstand the forces acting on it without unacceptable plastic deformation or breakage. This is ensured by calculations that determine the maximum stresses and deformations in the component and compare them with the permissible limit values.

Our range of services

static strength verifications - load and standard-compliant

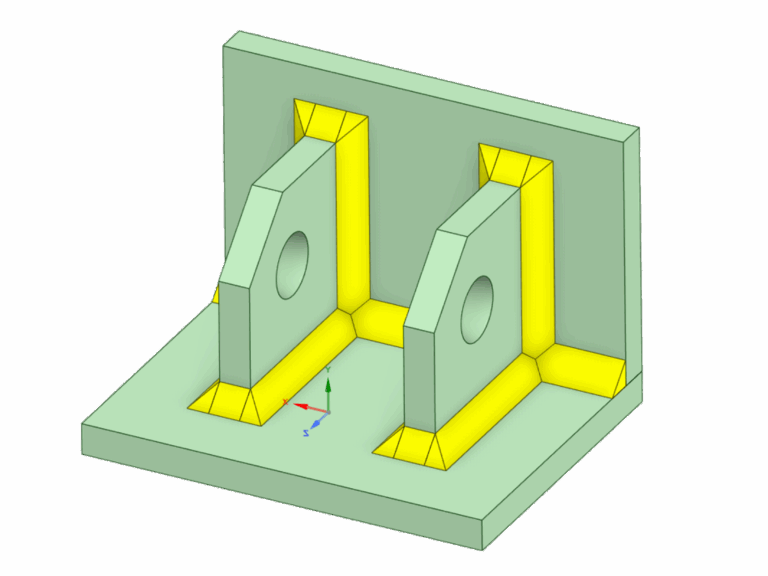

As an engineering office for static strength calculations, we evaluate the load-bearing capacity of your components reliably and in accordance with standards. Based on FEA analyses, we identify weak points or optimization potential at an early stage and ensure compliance with relevant guidelines - efficiently and precisely.

Learn more

Learn moreWeld seam calculation

Load-compliant design of weld seams for static and cyclic stresses.

Learn more

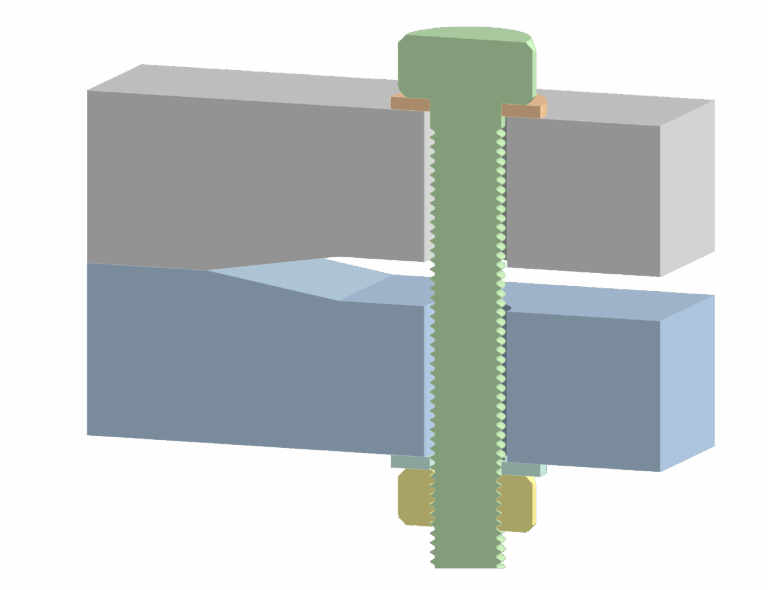

Learn moreScrew calculation

Bolt verifications check the load-bearing capacity of prestressed and non-prestressed connections - depending on the type of load.

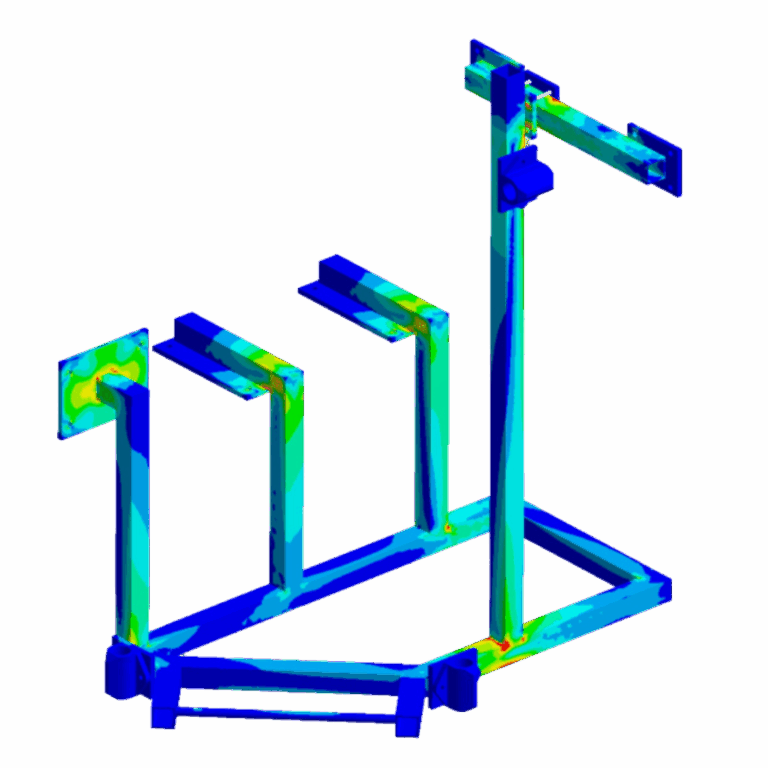

Component optimization

Increased competitiveness through targeted and effective component optimization, such as the use of materials.

Structural strength verifications are essential when...

Your safety - our responsibility

the function should already be ensured before use - for more safety and predictability.

a proof of strength is required - e.g. for CE documentation or approval procedures.

weak points at an early stage - even before the first physical prototypes are built.

development faster and more cost-effectively - with the help of targeted simulations.

the component behavior under load is decisive - the focus is on stresses and deformations.

Advantages of static strength verifications

Measurable benefits. Verifiable quality.

With virtual simulations and sound calculations, we support you in developing products faster, safer and more economically. Our claim: reliable results that you can rely on.

Prevention of component failure

A static strength verification can be used to ensure that the component can withstand the loads acting on it. This protects people and property.

Dimensioning of components

We determine the required dimensions and material properties to ensure a safe and resilient component.

Optimization of constructions

The results can be used to optimize the design. This reduces costs and can improve the availability of semi-finished products.

Our expertise for your project

We look forward to your inquiry!

As a specialized engineering office for FEA calculations and simulations, we offer you sound technical support in the preparation of standard-compliant strength verifications for your components in accordance with current regulations for static loads.

Do you have questions, need an assessment or want to get started right away?

We look forward to hearing from you – by phone, e-mail or in person.

Your contact person: Jonas Compart

elbcore engineers GmbH

Lerchenstraße 28a

22767 Hamburg

Do you have an exciting project?

Tell us about it.

Arrange a consultation now or send us a project inquiry.

Frequently asked questions (FAQ)

Quick answers. Clear solutions.

Which directives and standards can be covered?

We prepare static strength verifications in accordance with common guidelinessuch as Eurocode 3 (DIN EN 1993), the FKM guideline or the VDI 2230 guideline for bolts. We can also cover various standards for the design of pressure vessels, such as AD-2000, DIN EN 13445 and the ASME Code. If your guideline is not listed here, please do not hesitate to contact us!

In which development phase is a strength verification useful?

Weak points can be identified at an early stage in the design process and subsequent changes avoided – before real prototypes are created. You benefit from the many years of experience of our engineers.

Can existing constructions also be tested?

Yes, a subsequent assessment of the load-bearing capacity is also possible for components that already exist or are already in use – e.g. in the case of conversions or if CE certification is subsequently sought.

What is the difference between a static and cyclic strength verification?

The static verification evaluates the load-bearing capacity under a single or static load. The cyclic(fatigue) verification assesses the behavior under repeated loading over time.

Do you still have questions? We are here for you.

Contact us now