Shock calculation

Safety under shock loads. The dynamic analysis shows at an early stage whether your component can withstand short-term shock effects – regardless of the industry.

Reliable simulation of shock effects

Dynamic safety under extreme loads

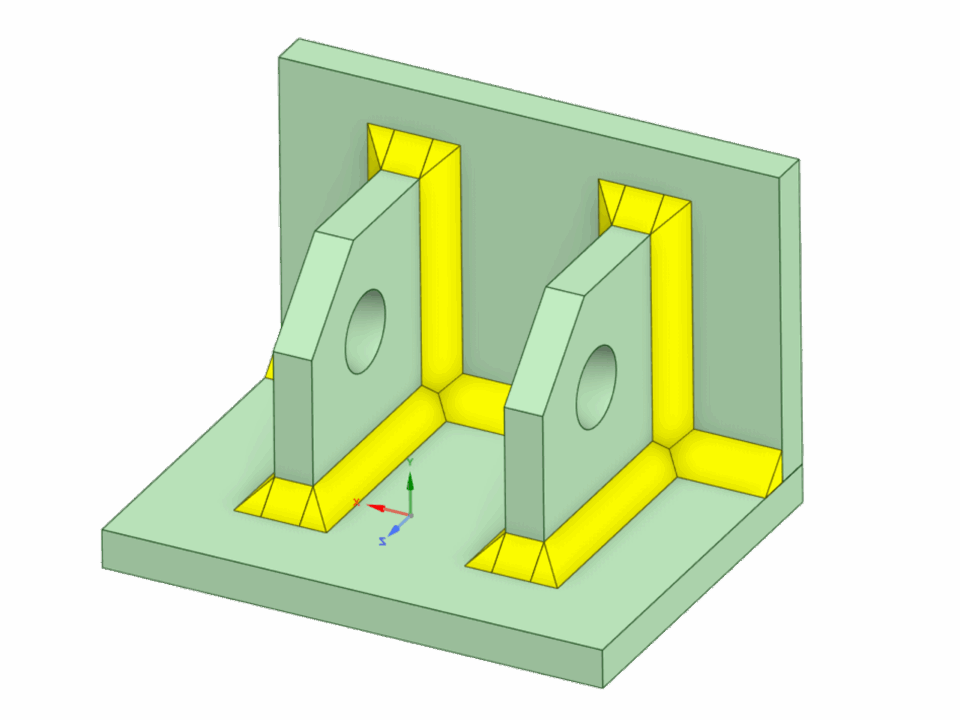

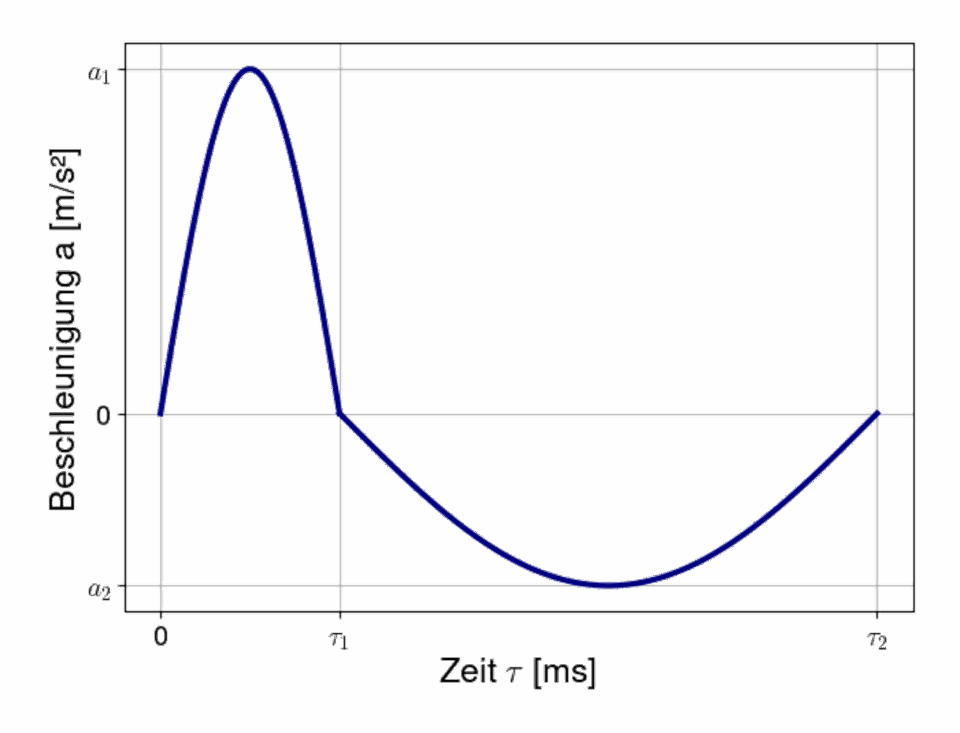

A shock analysis is a method from numerical structural mechanics that is used in product development to test the resistance of a component to short-term, impulse-like loads. Such shock loads are caused by impact events, rapid changes in movement or mechanical shocks – in contrast to static or oscillating loads.

The shock calculation ensures that your component can withstand the dynamic forces that occur – without unacceptable deformation or structural failure. Transient simulations are used to determine how stresses and deformations develop over very short periods of time – and whether they are within safe limits.

Our range of services

Safety and special simulations

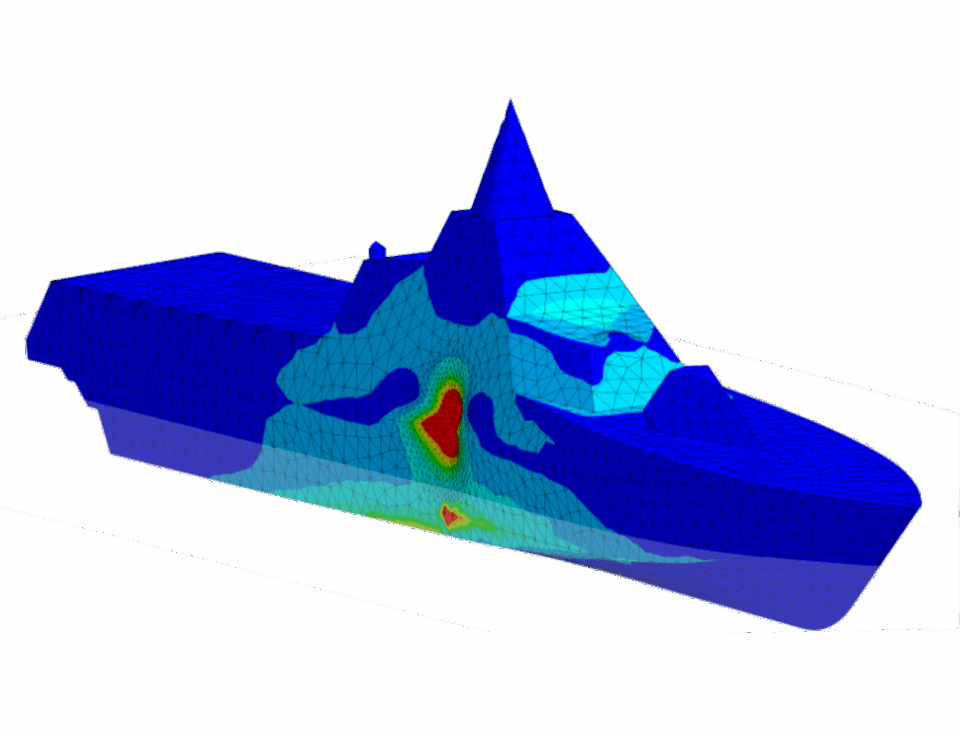

We evaluate the load-bearing capacity of your structures under shock - digitally, reliably and in accordance with standards. Using transient FEA analyses, we identify weak points, test safety-critical scenarios and create the basis for robust, safe use.

Learn more

Learn moreWeld seam calculation

Load-compliant design of weld seams for static and cyclic stresses.

Learn more

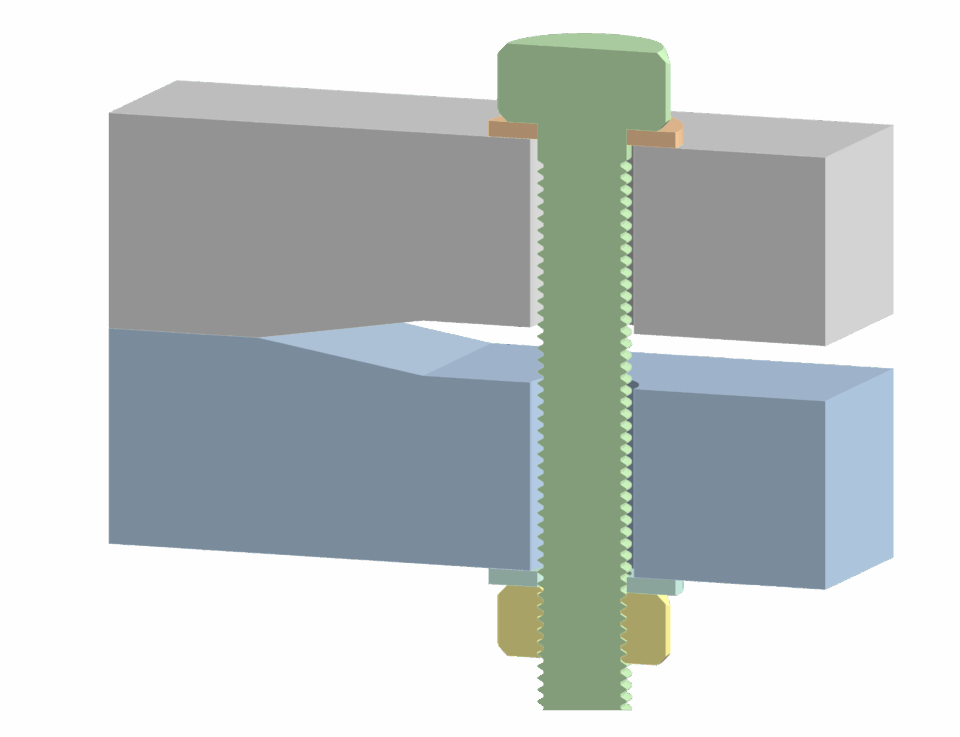

Learn moreScrew calculation

Bolt verifications check the load-bearing capacity of prestressed and non-prestressed connections - depending on the type of load.

Component optimization

Increased competitiveness through targeted and effective component optimization, such as the use of materials.

Shock calculations are essential when...

Your safety - our responsibility

short-term, impulse-like loads act on your construction - e.g. due to impacts, hard contacts or dynamic machine influences.

weak points in dynamic load cases before real tests are carried out.

high demands are placed on functionality and safety under transient loads - for example in electronics, sensor technology or fastenings.

there is no time for repeated prototype tests - and reliable simulation results are required.

Critical applications in sensitive industries such as defense, aviation or medical technology require maximum reliability.

Advantages of shock simulations

Measurable benefits. Verifiable quality

With virtual simulations and transient analyses, we support you in designing safer and more robust products. Our claim: reliable results for shock load cases - reliable, comprehensible and close to the application.

Prevention of component failure

A shock calculation can be used to check whether your component can withstand short-term dynamic loads. This reduces risks and prevents safety-relevant failures.

Design for dynamic load cases

We determine relevant stresses, deformations and impulses under impact load in order to specifically safeguard the design for critical load scenarios.

Realistic valuation

Digital shock simulations provide reliable findings even before the first physical tests are possible - and thus create planning security.

Our expertise for your project

We look forward to your inquiry!

As a specialized engineering office for FEA calculations and simulations, we offer you sound technical support in the preparation of verifiable strength verifications for your components under shock.

Do you have questions, need an assessment or want to get started right away?

We look forward to hearing from you – by phone, e-mail or in person.

Your contact person: Jonas Compart

elbcore engineers GmbH

Lerchenstraße 28a

22767 Hamburg

Strong across all sectors

Our services are used throughout the industry

Our engineering services are used in a wide range of industries - wherever safety, efficiency and technical precision are required.

Plant & tank construction

Electrical engineering

Mechanical engineering

Metal / steel construction

Shipbuilding

Special machine construction

Valve & pump technology

Your sector not listed?

Now contacted

Do you have an exciting project?

Tell us about it.

Arrange a consultation now or send us a project inquiry.

Frequently asked questions (FAQ)

Quick answers. Clear solutions.

Here you will find answers to the most frequently asked questions about our services.

What exactly is a shock calculation?

A shock calculation is a dynamic simulation in which the behavior of a component under short-term, shock-like load is analyzed – e.g. as a result of an impact or hard contact.

When is a shock analysis useful?

Particularly in early development phases or for safety-critical applications – such as in the defense industry, aviation, medical technology or mobile devices – shock analysis provides valuable insights before the first prototypes are built.

Can existing constructions also be checked?

Yes, existing models or CAD data can be used to subsequently simulate the behavior under shock and, if necessary, identify potential for improvement.

How long does a shock simulation take and how much does it cost?

This depends on the component, the boundary conditions and the level of detail. A calculation usually takes a few days. We would be happy to provide you with an individual offer.

Do you still have questions? We are here for you.

Contact us now