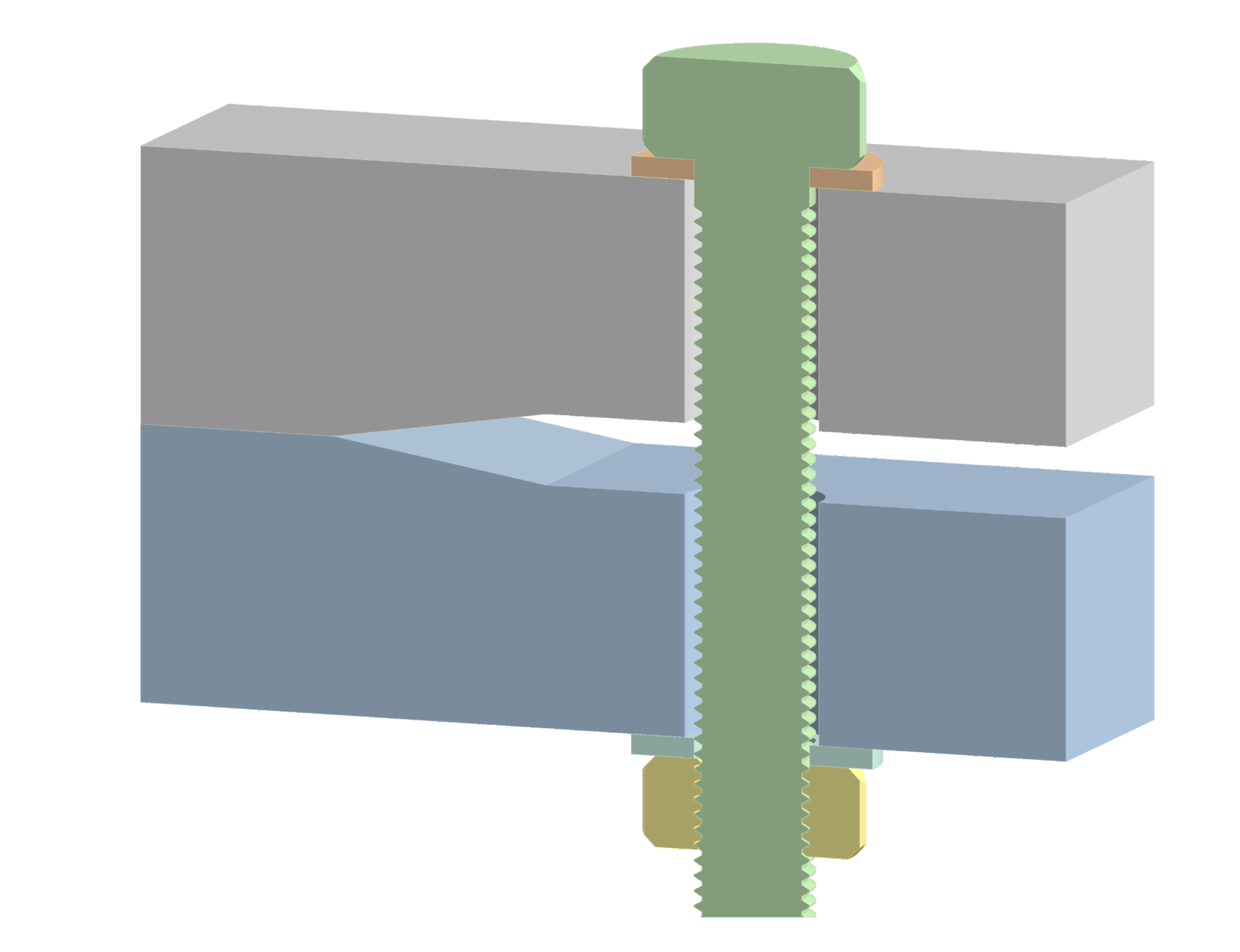

Screw calculation and design

We calculate and dimension bolted connections in accordance with standards and loads – individually tailored to your technical requirements.

Binding evaluations of your components

Analyze bolted joints. Secure strength in a targeted manner.

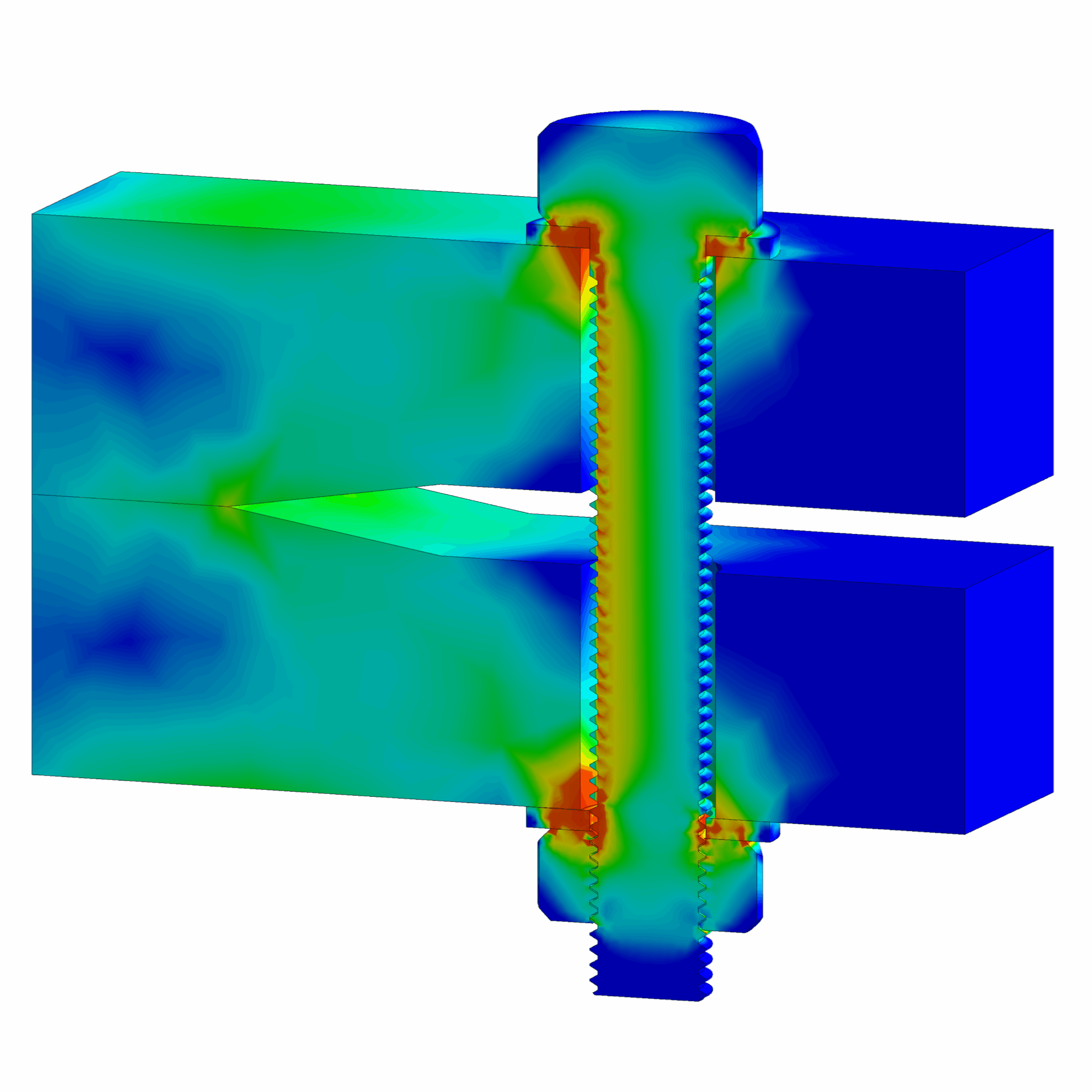

A strength verification of bolted connections is crucial for the safe design of mechanical constructions – for example in mechanical engineering, automotive engineering or steel construction. Screws are often subjected to combined loads such as tension, shear and possibly bending – often under dynamic conditions.

The calculation takes into account geometry, preload, friction, load collectives and material properties – in accordance with applicable standards such as VDI 2230 or DIN EN 1993. The aim is to verify the load-bearing capacity, identify critical screw connections and avoid overdimensioning.

Our range of services

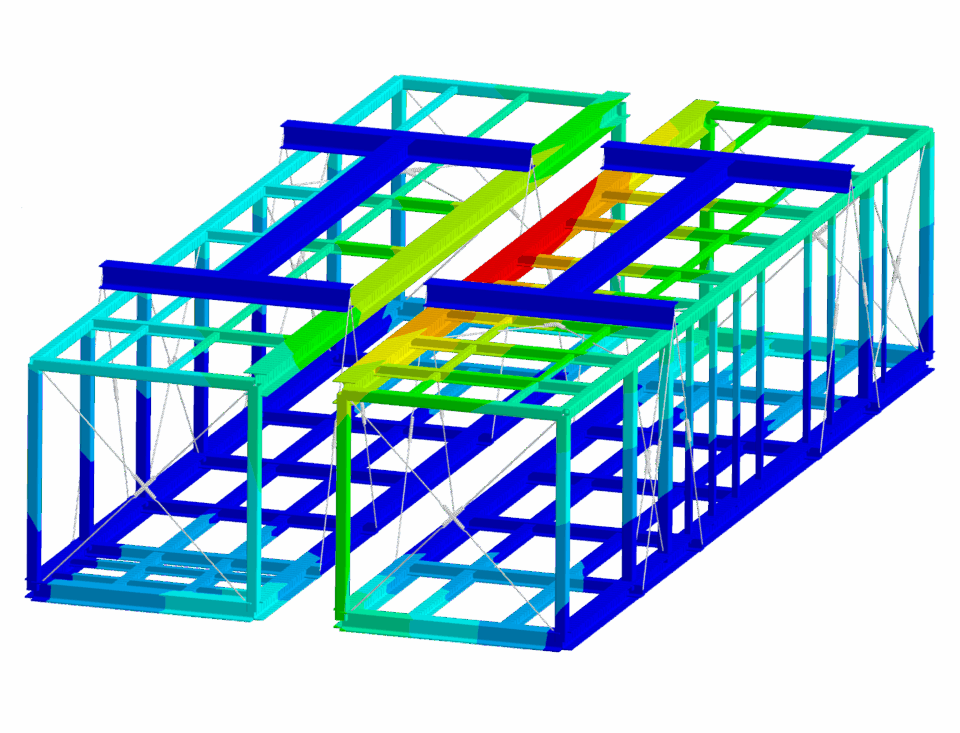

static strength verifications - load and standard-compliant

We use static strength analyses to reliably assess the load-bearing capacity of your components in accordance with standards. Based on FEA analyses, you can identify weak points or optimization potential at an early stage and ensure compliance with relevant guidelines – efficiently and precisely.

Static strength verification

A static strength verification checks whether a component can withstand the intended loads permanently and safely.

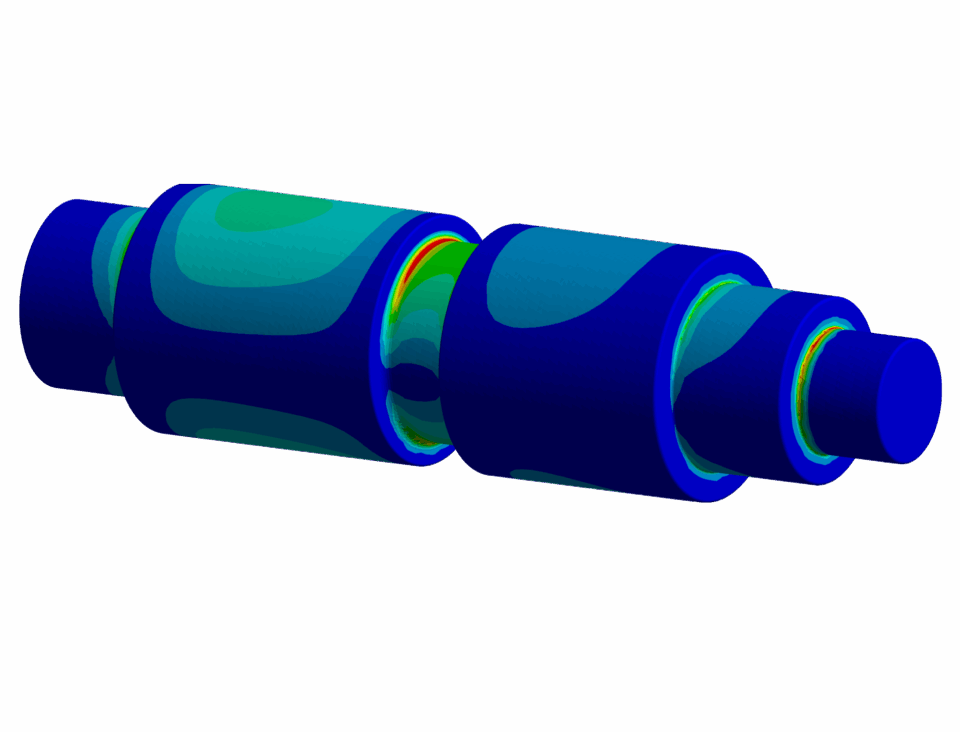

Fatigue strength verification

Fatigue describes the gradual failure of components under repeated, cyclical load.

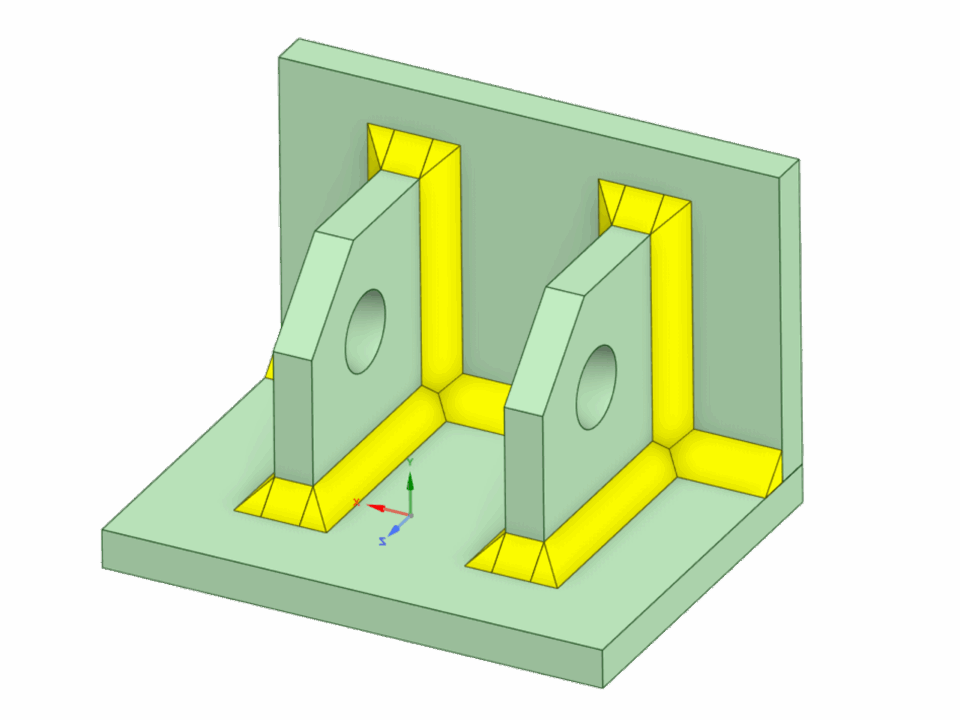

Weld seam calculation

Load-compliant design of weld seams for static and cyclic stresses.

Bolt calculations are essential when...

Your safety - our responsibility

screw connections are located in highly stressed areas - for example in the force flow - and must be evaluated as potential weak points.

load-bearing screw connections are subjected to dynamic or cyclic loads and proof of fatigue strength is required.

increased temperatures occur and the braced elements expand differently than the screw.

damage has already occurred during operation and it is now necessary to prevent this through design optimization.

if the bolted connection is safety-critical and failure could lead to personal injury or system failure.

Advantages of screw calculations

Measurable benefits. Verifiable quality.

Avoidance of screw failure

With the help of a well-founded bolt calculation, it can be ensured that the connection can withstand the actual operating loads. This allows risks of failure to be identified at an early stage and people and property to be effectively protected.Reliable design

We determine the required dimensions and preload forces for your screws - taking into account standards, loads and boundary conditions.Efficient screw design

An optimized design makes it possible to make bolted connections slimmer, lighter or with fewer components - without compromising on safety.

Our expertise for your project

We look forward to your inquiry!

As a specialist engineering office for FEA calculations, we offer you sound technical support in the design, optimization and evaluation of bolted connections. Whether static, dynamic or thermally influenced loads – we check whether your connection can withstand the requirements in the long term.

Do you have questions, need an assessment or want to get started right away?

We look forward to hearing from you – by phone, e-mail or in person.

Your contact person: Jonas Compart

elbcore engineers GmbH

Lerchenstraße 28a

22767 Hamburg

Do you have an exciting project?

Tell us about it.

Arrange a consultation now or send us a project inquiry.

Frequently asked questions (FAQ)

Quick answers. Clear solutions.

Which standards apply to the screw calculation?

VDI 2230 – in particular Sheet 1 – is the authoritative guideline for the verification of bolted connections. It describes a detailed calculation method for determining bolt forces, preload and safety, both in the static and dynamic range. In structural engineering applications, particularly in steel construction, DIN EN 1993 (Eurocode 3) may also be relevant, as it specifies design rules for bolted connections in the context of structural design.

Can bolted joints be reliably modeled in a FEA simulation?

Yes, FEA simulations are very well suited to analyzing bolted joints realistically – especially with complex geometries or when local stress distributions need to be considered. In practice, we often combine numerical simulations with analytical calculations in accordance with VDI 2230 in order to achieve reliable and comprehensible results.

What information do you need to carry out a screw calculation?

For a well-founded calculation, we need information on the geometry and arrangement of the screws, on the loads that occur (such as forces and torques), on the materials used and on assembly parameters such as preload force and coefficient of friction. In addition, boundary conditions such as temperature or dynamic loads may also be relevant.