Safety and special calculations

Diverse applications and systems can be exposed to special challenges, such as an explosion, special transportation or a shock. We check your components reliably and digitally.

Digital safety analyses for the highest loads

safety right from the start

Our simulation solutions help you to prepare systems and components for extreme scenarios – whether explosions, shock waves, containment or dynamic shock loads. Instead of risky and expensive physical tests, we analyze digital models realistically and efficiently. This saves time and money.

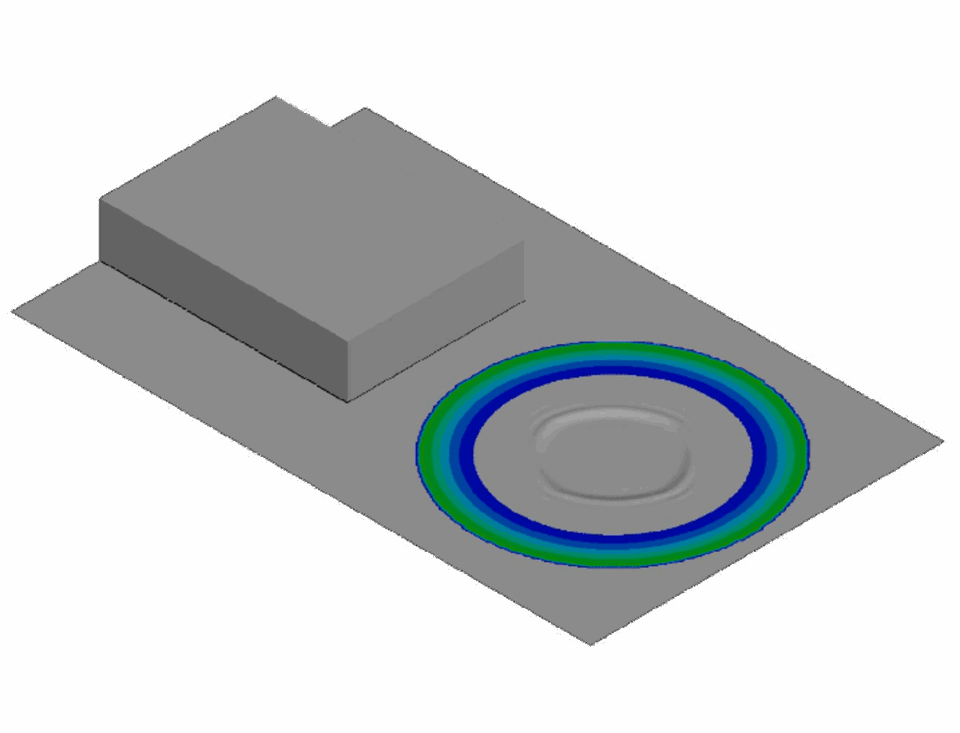

Using numerical methods such as FEA and CFD calculations, we simulate the propagation of pressure or shock waves, investigate structural damage and test the effectiveness of protective measures. This allows you to identify weak points at an early stage, optimize your design and comply with safety-related standards – even before the first prototype is built.

Our range of services

Services that are tailored to your requirements

Based on FEA and CFD analyses, we determine the behavior of your process or systems under extraordinary loads and situations. From crash simulations to explosion calculations, shock calculations and transport simulations, we can digitally map a wide range of such challenges.

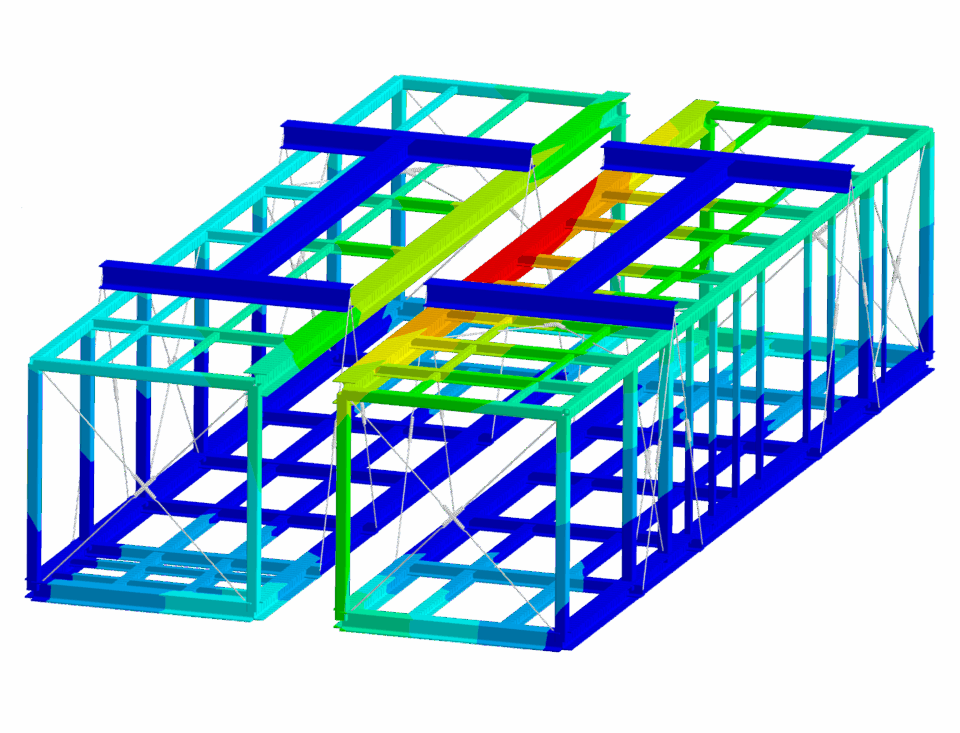

Crash simulations

Understand what happens in the event of a crash and improve the design of your structures.

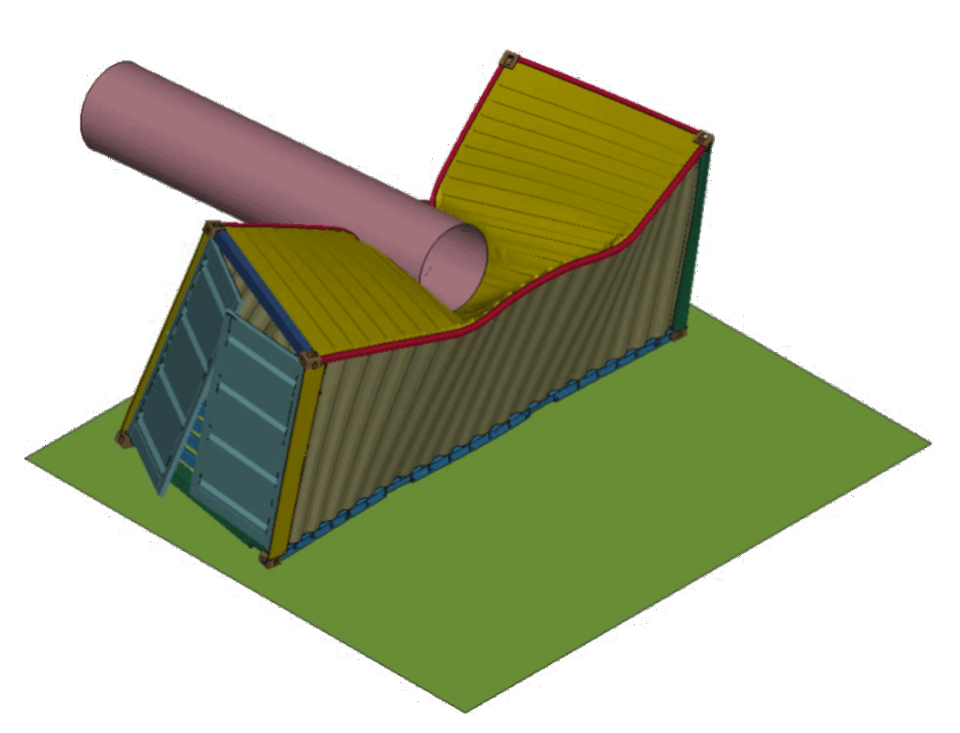

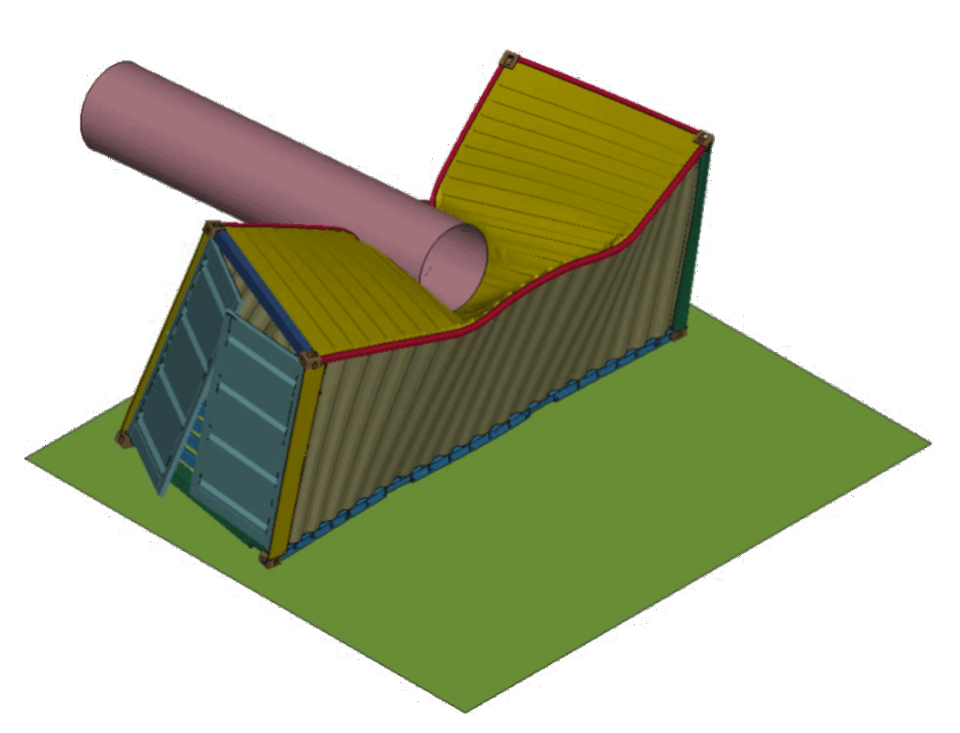

Explosion calculation

We show how safe your component is in the event of an explosion, e.g. due to a short circuit or gas ignition

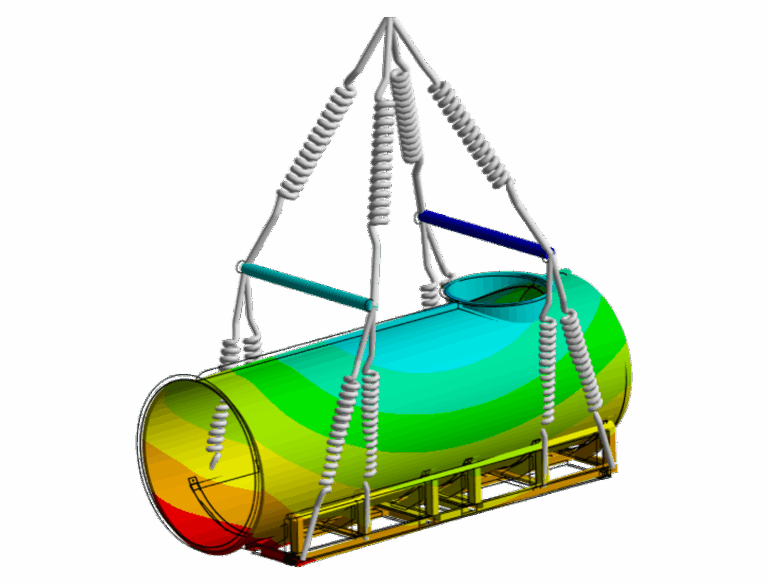

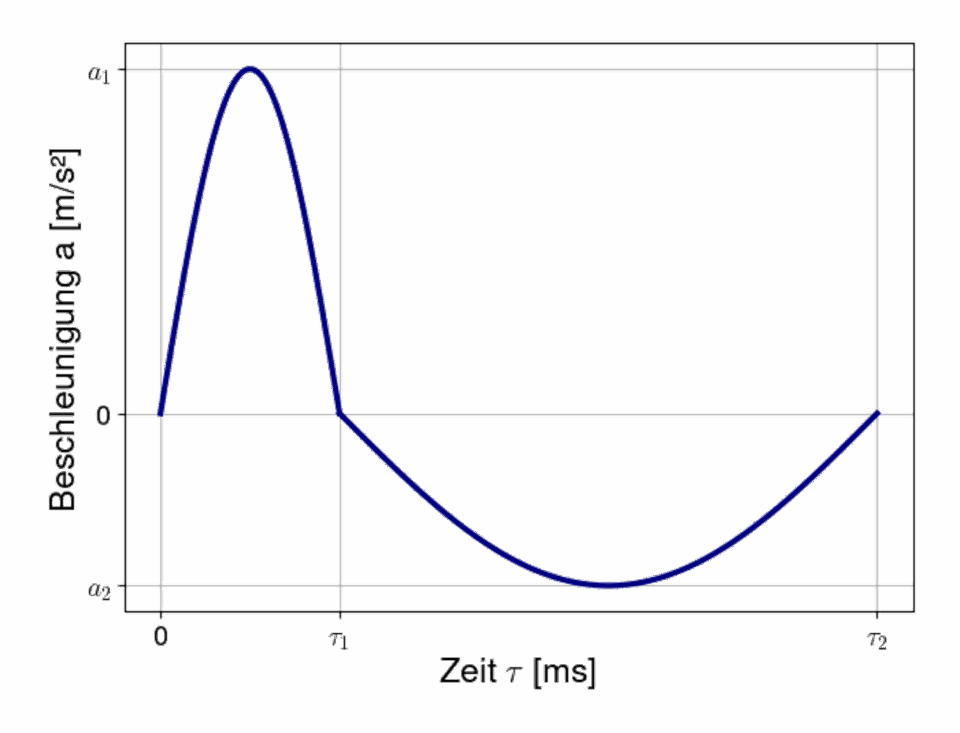

Shock calculations

Shock loads can lead to unintentional destruction of your components. We simulate this and identify critical points.

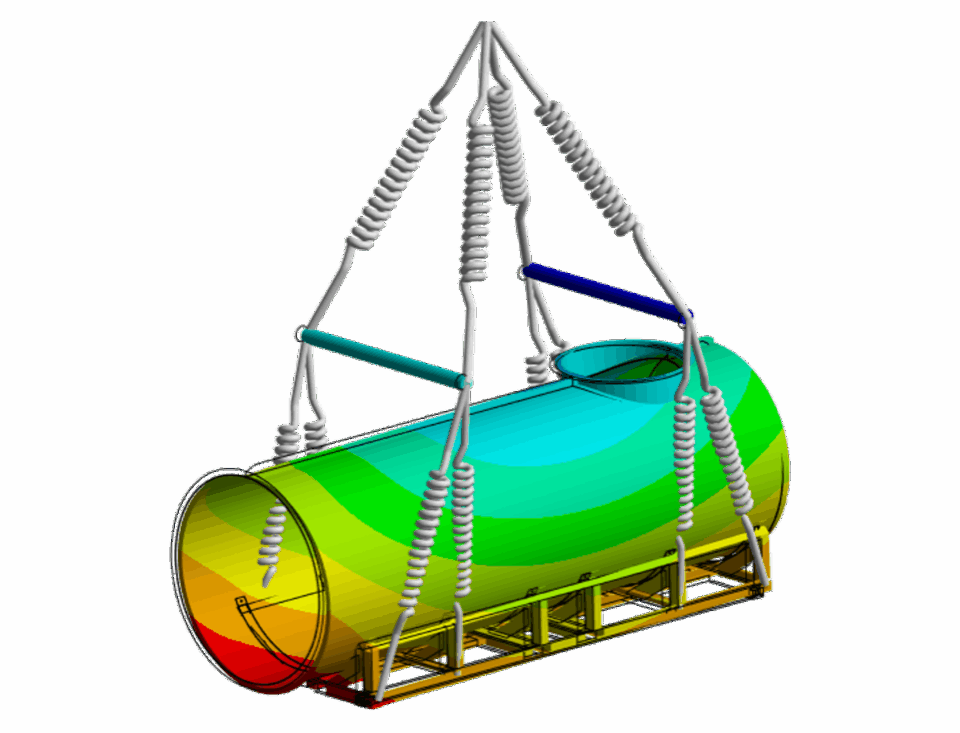

Transport simulations

Depending on the type of transport, this can cause different loads on your component, e.g. when lifting by crane

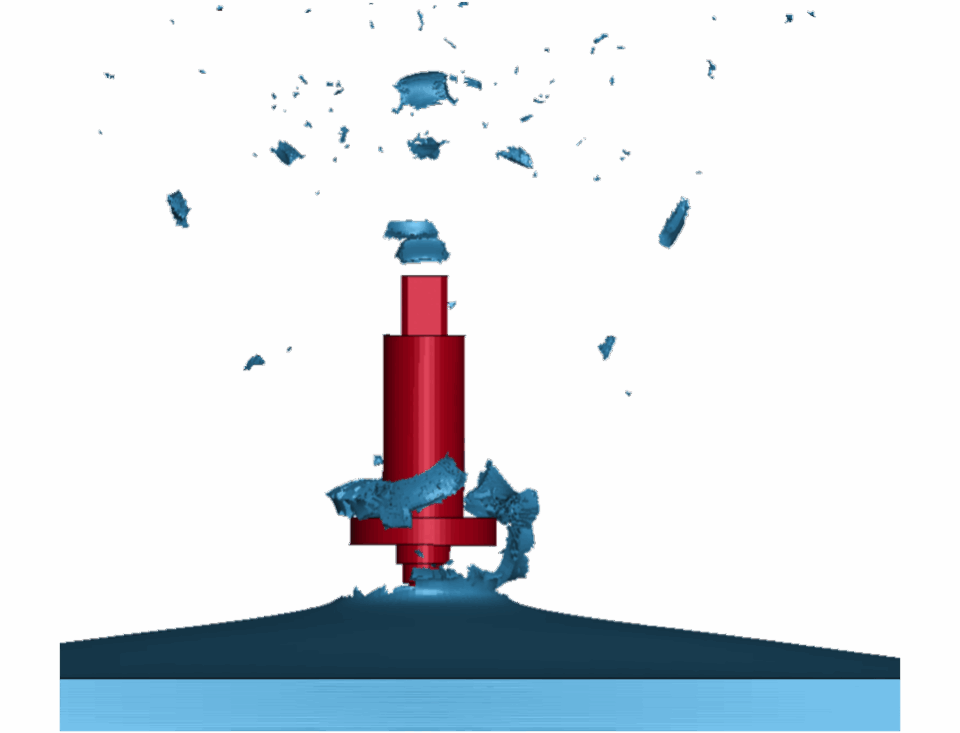

Containment

Make your systems and machines puncture-proof. This is particularly important for pressure test benches, for example, to protect human life.

Interested in our services?

Secure your exclusive 30-minute video call to discuss your project and benefit from the advantages of calculations and simulations!

You've come to the right place if...

Your challenges - our solutions

You want to understand how your components behave in the event of a crash, transportation or explosion - before damage occurs.

you want to safeguard critical load cases - for example through shock, crash or explosion calculations.

you need to prove that your components are pressure-tight or puncture-proof - e.g. for containment applications.

you want to realistically simulate complex transportation or accident scenarios in order to validate or validate designs.

you want to save time and money with virtual tests - instead of time-consuming physical tests.

Advantages of simulations

Measurable benefits. Verifiable quality

With virtual simulations and sound calculations, we support you in developing products faster, safer and more economically. Our claim: reliable results that you can rely on.

Proof of safety

Mechanical loads caused by crashes, explosions or shocks can be realistically simulated and evaluated - creating safety in product design and approval.

Avoidance of damage

Numerical simulations allow weak points to be identified at an early stage. This allows you to avoid consequential damage, unnecessary tests and unplanned breakdowns or accidents during operation.

Efficient development

Changes can be evaluated quickly and cost-effectively. Virtual tests save time and significantly reduce the effort required for physical tests - right up to the finished solution.

Our expertise for your project

We look forward to your inquiry!

As a specialized engineering office for simulations, we offer you sound technical support in the development and analysis of your components – especially for challenging environmental conditions and areas of application.

Do you have questions, need an assessment or want to get started right away?

We look forward to hearing from you – by phone, e-mail or in person.

Your contact person: Jonas Compart

elbcore engineers GmbH

Lerchenstraße 28a

22767 Hamburg

Strong across all sectors

Our services are used throughout the industry

Our engineering services are used in a wide range of industries - wherever safety, efficiency and technical precision are required.

Armor

Chemical & process industry

Automotive industry

Aerospace

Energy & power plant technology

Mechanical and plant engineering

Electronics & semiconductor indistrue

Your sector not listed?

Now contacted

Do you have an exciting project?

Tell us about it.

Arrange a consultation now or send us a project inquiry.

Frequently asked questions (FAQ)

Quick answers. Clear solutions.

Here you will find answers to the most frequently asked questions about our services.

What information do we need to provide in order to start a project?

For a realistic simulation, we ideally need your CAD data, information on materials, bearings, loads and the objective of the investigation – e.g. proof of safety, damage analysis or design for special load cases. Simply send us your data using our inquiry form – we will check what is possible without obligation.

How long does a typical safety or special simulation take?

This depends on the task, the complexity of the geometry and the desired accuracy. Initial results are often possible within a few days for straightforward projects. More comprehensive analyses or variant studies can take several weeks. We would be happy to clarify this in a personal meeting.

Do you also provide support in interpreting and optimizing results?

Yes – we not only provide you with reliable results, but also specific recommendations, e.g. for reinforcing components, positioning safety zones or deriving design measures. Use our experience to gain practical solutions from the simulation.

What software do you use - and how reliable are the results?

We use established FEA tools such as ANSYS Mechanical, LS-DYNA and OpenRadioss, depending on the application. The results are backed up by internal quality standards, comparative calculations and – on request – validation with tests. Please contact us for sample projects.

Is such a simulation also worthwhile for smaller companies or individual projects?

Definitely – especially in safety-critical or expensive test situations, simulations can offer enormous savings potential. The use of simulations also makes economic sense for medium-sized companies or specific individual issues. We will be happy to advise you individually.