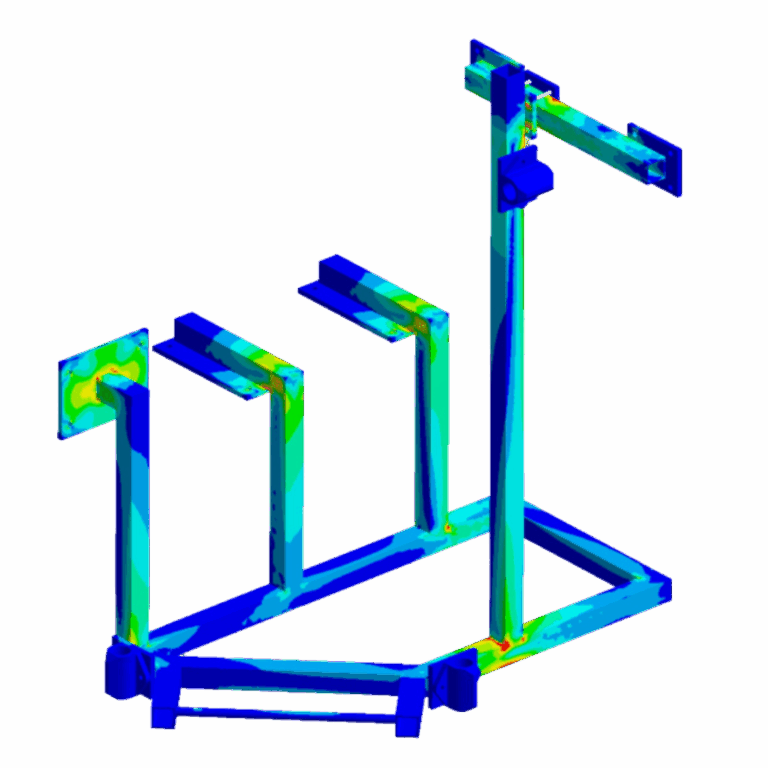

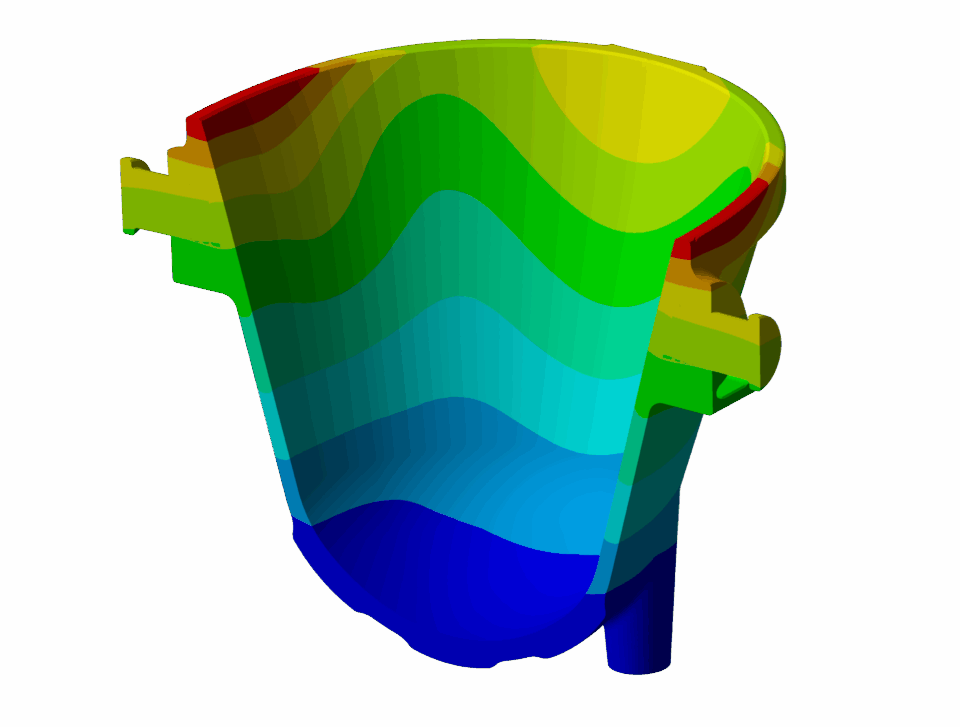

FEA-Calculation / structural simulation

Understanding what is happening in your component. With FEA calculations, we make the invisible visible – early, digitally and reliably. This allows you to recognize risks before they arise.

Simulation instead ofexpensive prototypes

FEA-Simulation for real clarity

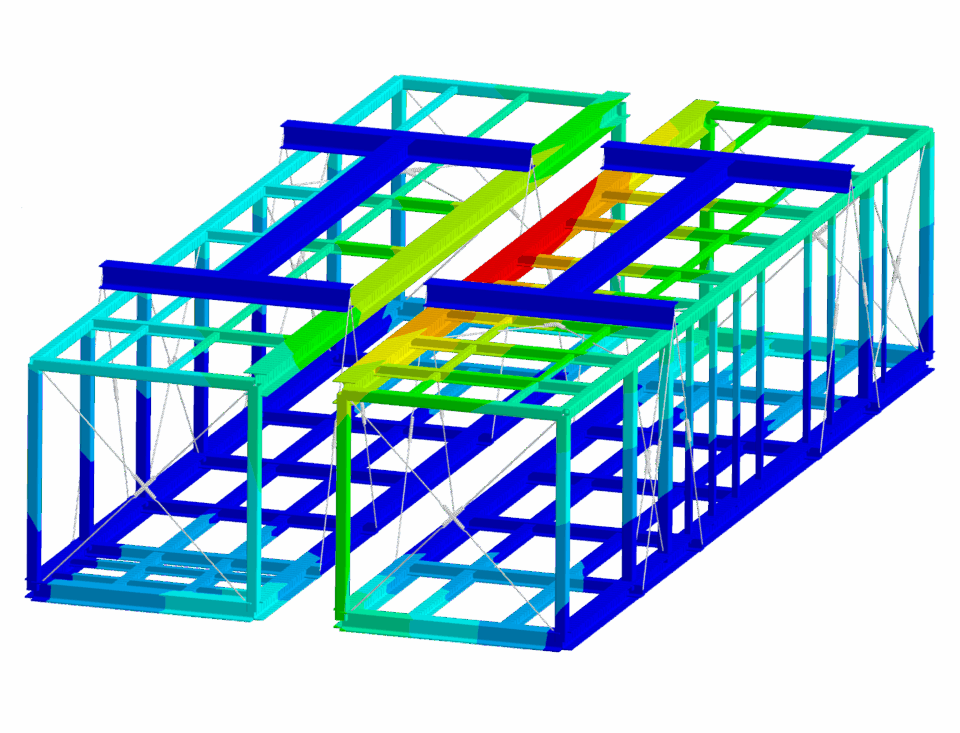

FEA-Calculations are a helpful tool for product development in order to visualize the behaviour of materials, components and assemblies under different conditions or loads. Errors in the construction or design can be detected at an early stage with the help of a structural simulation. This allows you to save valuable time and resources while maximizing your profits.

As a FEA service provider, we use FEA calculations to make physics visible and provide you with digital insights into your product development that would otherwise have remained physically hidden. This not only saves you time and valuable resources.

Our range of services

FEA-Services that are tailored to your requirements

With FEA calculations, we make the behavior of materials, components and assemblies visible under real conditions - even before physical prototypes are created. This allows you to identify design errors at an early stage, save valuable resources and measurably accelerate your product development.

Learn more

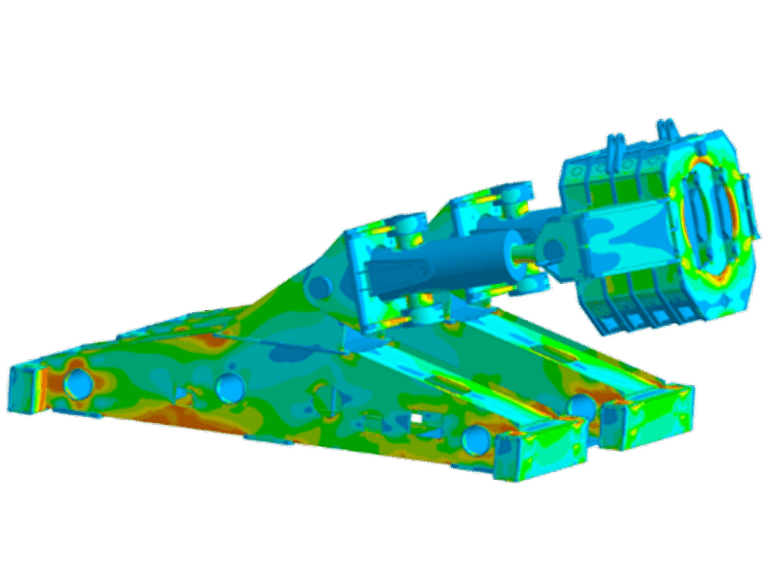

Learn moreStatic strength verification

A static strength verification checks whether a component can withstand the intended loads permanently and safely.

Learn more

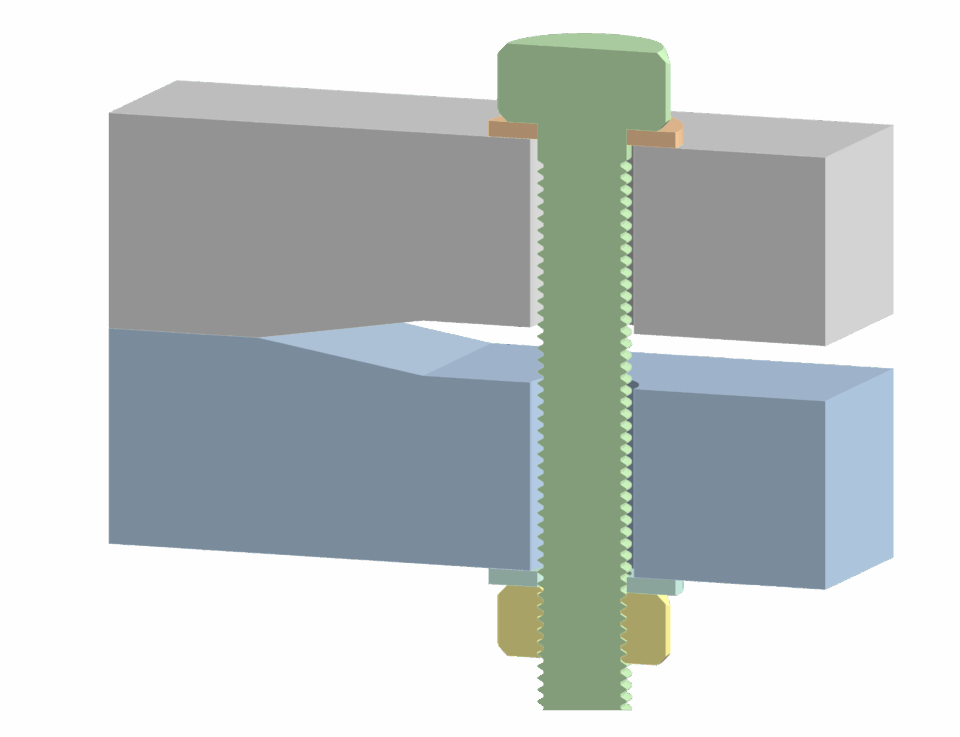

Learn moreScrew calculation

Bolt verifications check the load-bearing capacity of prestressed and non-prestressed connections - depending on the type of load.

Learn more

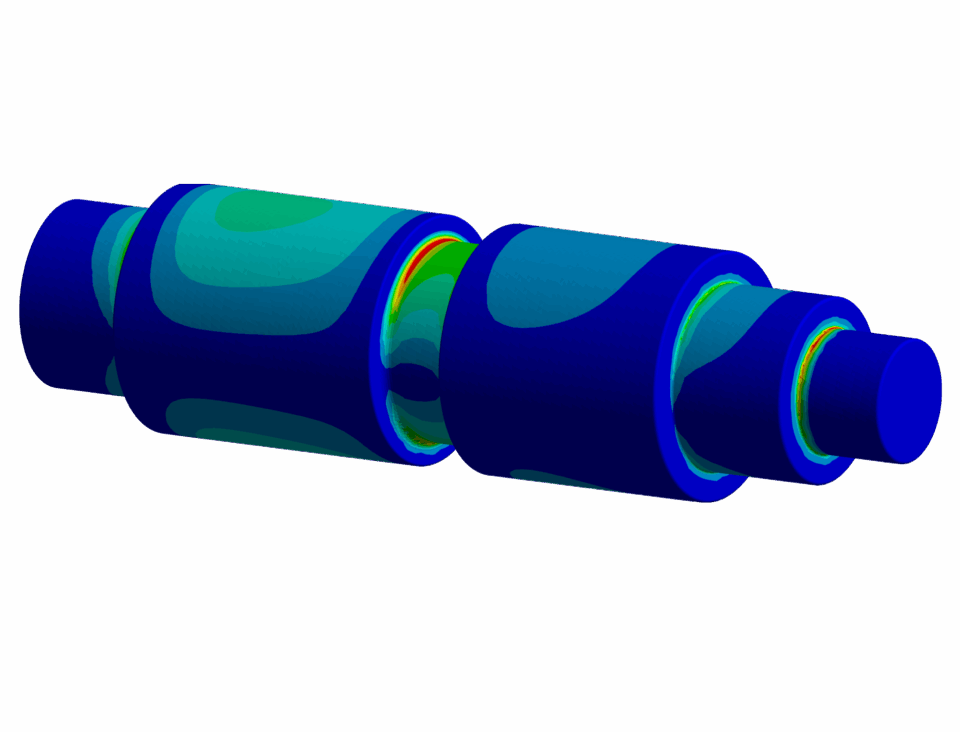

Learn moreFatigue strength verification

Fatigue describes the gradual failure of components under repeated, cyclical load.

FEA-Calculations are the right procedure when...

Your challenges - our solutions

you require a verifiable proof of strength or CE-compliant documentation, e.g. as part of the Machinery Directive 2006/42/EC.

you want to validate components as early as the development phase - using virtual prototypes to check function, weight and costs.

you want to identify risks at an early stage and save development time - through simulation-based evaluation before physical implementation.

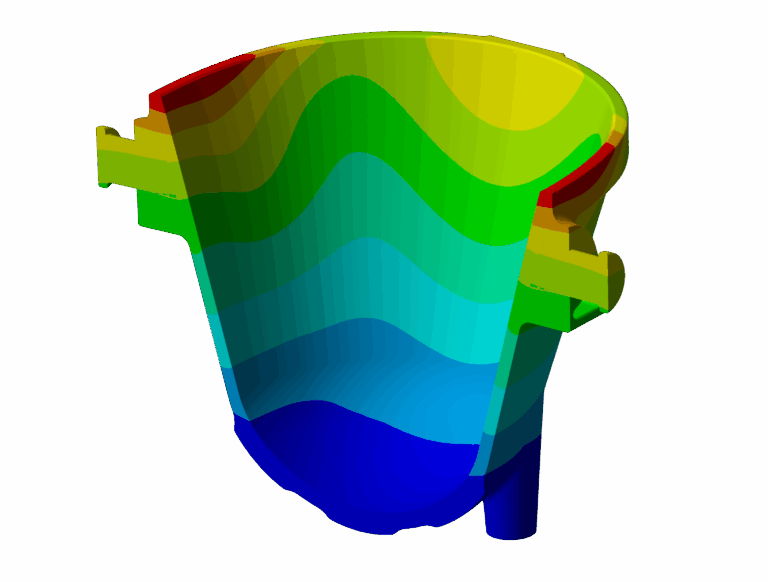

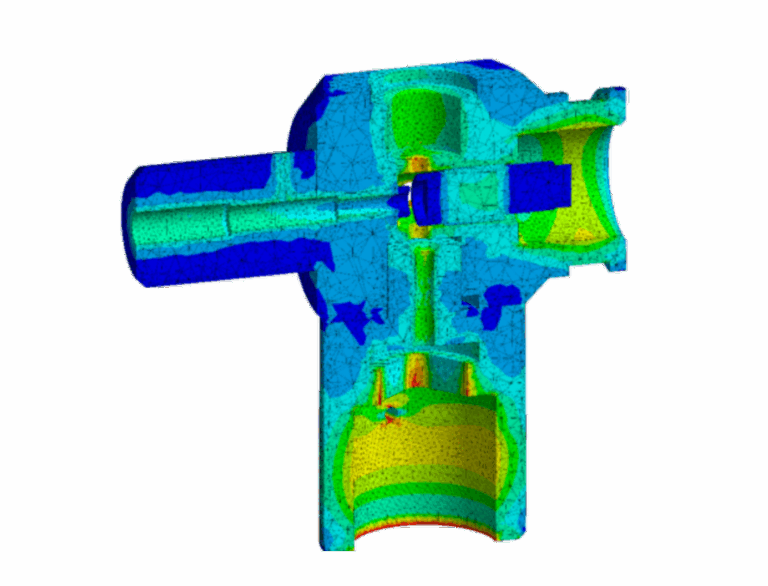

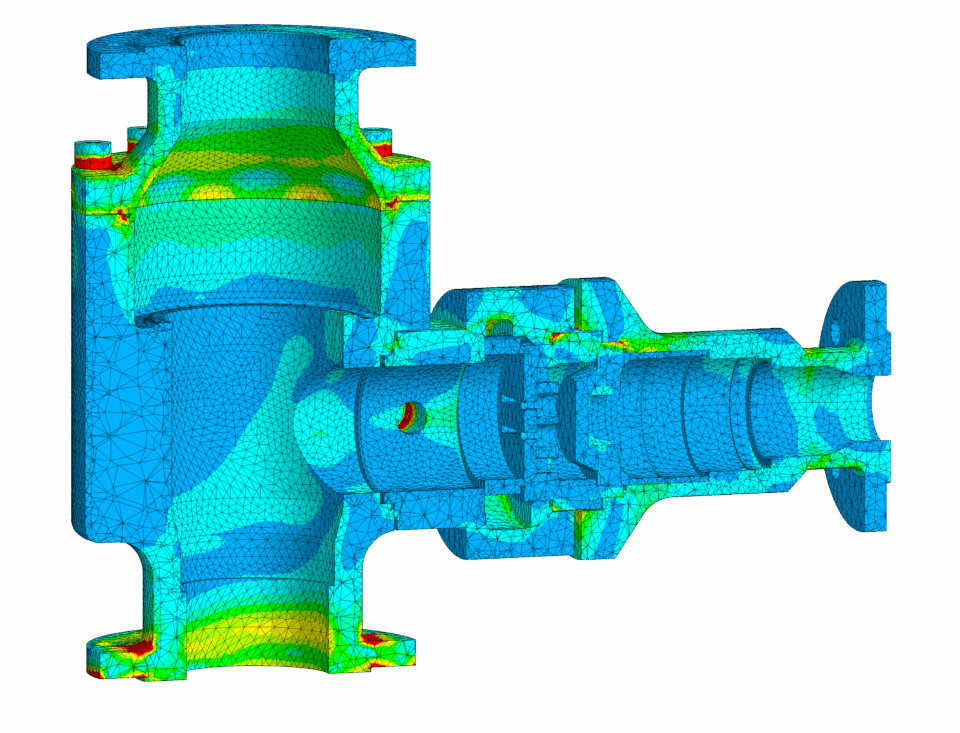

you want to physically understand complex component behavior, e.g. visualize stresses, currents, temperatures or deformations.

If real tests take too long or are too expensive, we can simulate variants, parameter studies or comparative tests for you.

Advantages of FEA calculations

Measurable benefits. Verifiable quality

With virtual simulations and sound calculations, we support you in developing products faster, safer and more economically. Our claim: reliable results that you can rely on.

Analysis of product properties

We examine the behaviour of your components under real load cases - precise, comprehensible and ideal for optimization in the early development phase.

Cost-efficient prototypes

Virtual simulations replace time-consuming test series - this saves development time, reduces costs and gets your ideas on the road faster.

Quickly ready for series production

Targeted calculations allow you to identify weak points at an early stage and reduce correction loops - for a smooth transition to production.

Our expertise for your project

We look forward to your inquiry!

As a specialized engineering office for FEA calculations and simulations, we offer you sound technical support in the design and evaluation of weld seams. Whether static or cyclic loads – we check whether your machine or construction can withstand the loads.

Do you have questions, need an assessment or want to get started right away?

We look forward to hearing from you – by phone, e-mail or in person.

Your contact person: Jonas Compart

elbcore engineers GmbH

Lerchenstraße 28a

22767 Hamburg

Strong across all sectors

Our services are used throughout the industry

Our engineering services are used in a wide range of industries - wherever safety, efficiency and technical precision are required.

Plant & tank construction

Electrical engineering

Mechanical engineering

Metal / steel construction

Shipbuilding

Special machine construction

Valve & pump technology

Your sector not listed?

Now contacted

Do you have an exciting project?

Tell us about it.

Arrange a consultation now or send us a project inquiry.

Frequently asked questions (FAQ)

Quick answers. Clear solutions.

Here you will find answers to the most frequently asked questions about our services.

What do you need from us so that you can get started as a FEA service provider?

For a structural-mechanical calculation, we usually need 3D CAD data, information on materials, loads, boundary conditions and – most importantly – your objective: Is it about strength, deformation, service life or optimization? Simply upload your data using our contact form or talk to us directly – as a FEA calculation office, we will check what is possible free of charge.

What tasks can we take on for you as a FEA service provider?

We use the finite element method to analyze component deformations, stresses, natural frequencies, stability (buckling), fatigue, thermal effects and much more – for steel, aluminium and other materials.Not sure whether FEA is suitable for your case? As an experienced FEA service provider, we will be happy to advise you without obligation.

How accurate and reliable are the results?

The quality of the results depends heavily on the boundary conditions, the material data used and the modeling. As a FEA service provider, we work with validated methods, check the plausibility of the results and compare them with standards (e.g. FKM, Eurocode) or measurement data.Put your trust in our experience – we deliver reliable results you can rely on.

How do we support you beyond pure FEA simulation?

As a service provider at FEA, we see ourselves as a technical partner: We identify optimization potential, help with weight reduction, material savings or service life extension – and support you from the concept phase through to series release.Benefit from in-depth analysis and practical recommendations.

Does a FEA service provider also make sense for small series, prototypes or individual parts?

Especially for limited quantities or security-relevant applications, FEA is particularly worthwhile – because you can avoid oversizing and identify risks at an early stage.Whether you are a start-up or a medium-sized company: as a flexible FEA service provider, we offer solutions that fit your project budget.

Do you still have questions? We are here for you.

Contact us now