Fatigue strength verification

Safety that lasts. The fatigue strength verification shows at an early stage whether your component will remain failure-free even under cyclic loading – reliably, in accordance with standards and economically.

Lasting safety for your constructions

Recognize fatigue. Avoid failures.

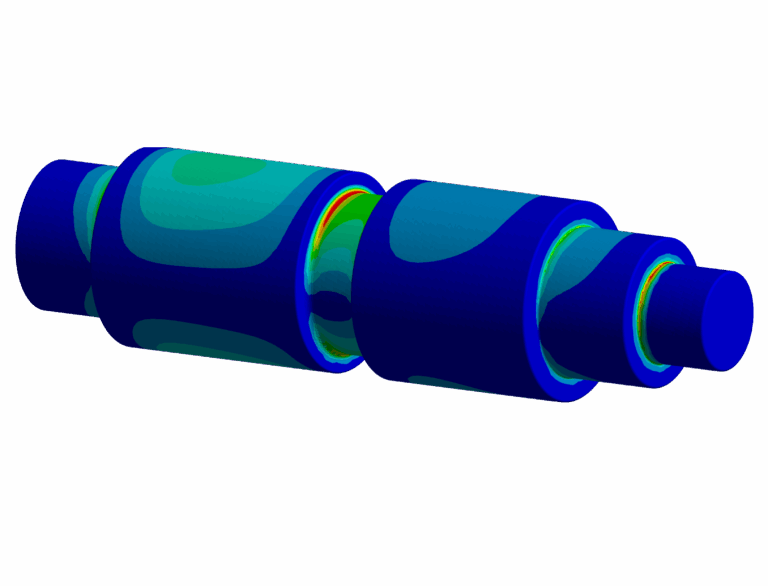

A fatigue strength test is a key procedure in mechanical engineering, vehicle construction and other industries to evaluate the service life and operational safety of components under cyclical or alternating loads. Such dynamic loads are caused by recurring forces or moments such as rotation, vibration or pressure pulses and can lead to cracking and failure in the long term.

The fatigue strength calculation shows how many load cycles a component can withstand without damage. For this purpose, stresses, notches and material characteristics are analyzed and evaluated using standard-compliant methods such as the FKM guideline or on the basis of experimental Wöhler curves. The aim is to identify potential weak points at an early stage and verify the operational stability of your design.

Our range of services

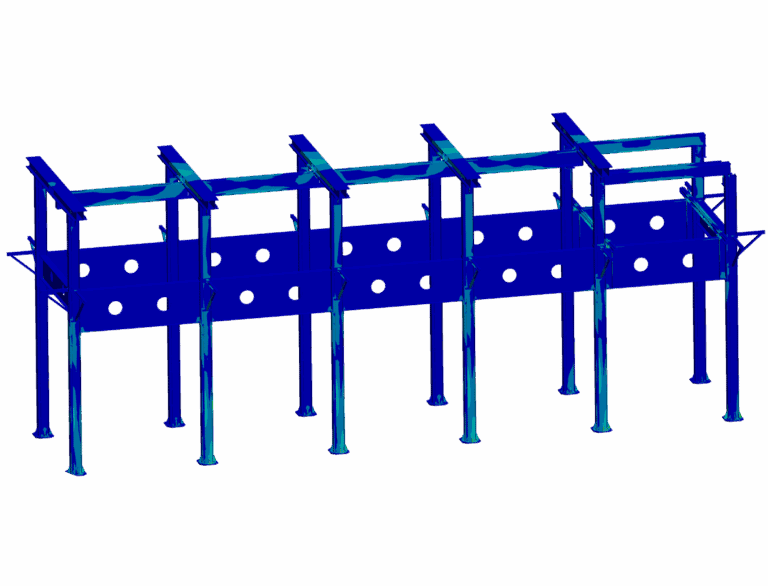

Fatigue strength verifications - Permanently safe

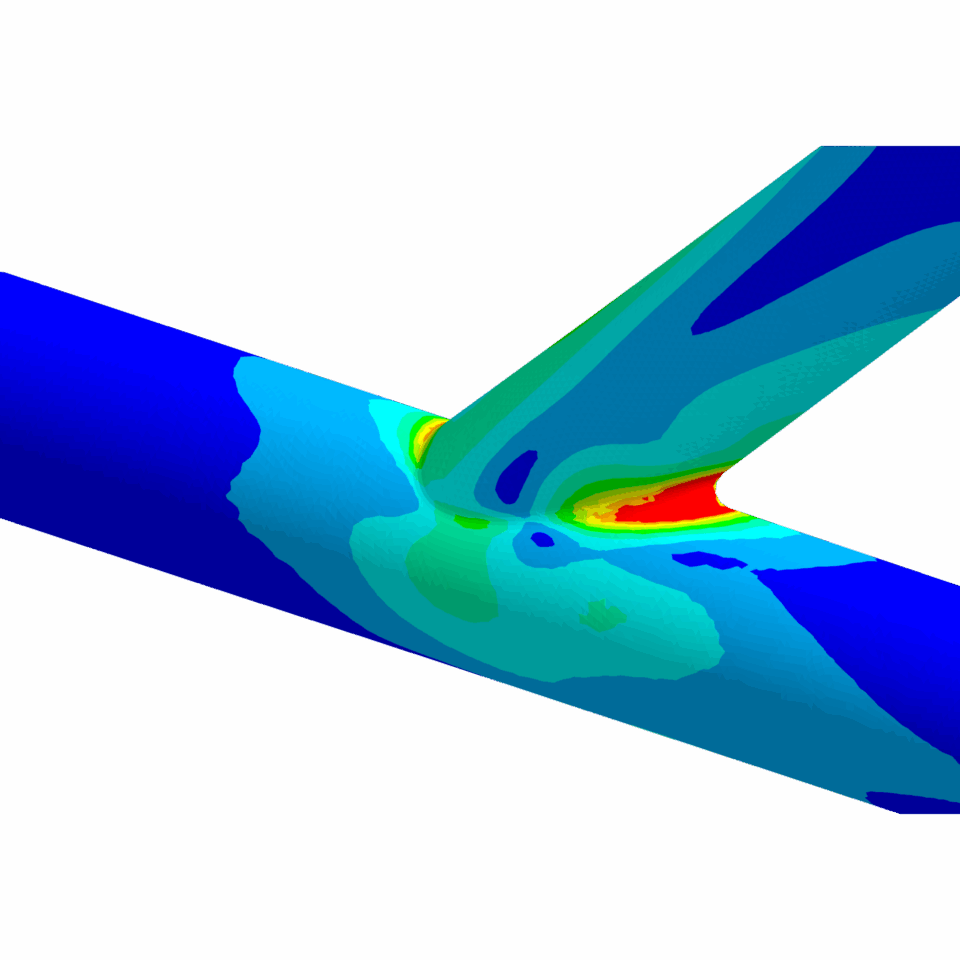

We use fatigue strength verifications to reliably evaluate the fatigue strength of your components in accordance with standards. Based on FEA analyses , you can identify critical points under alternating loads at an early stage and ensure compliance with relevant guidelines - efficiently and precisely.

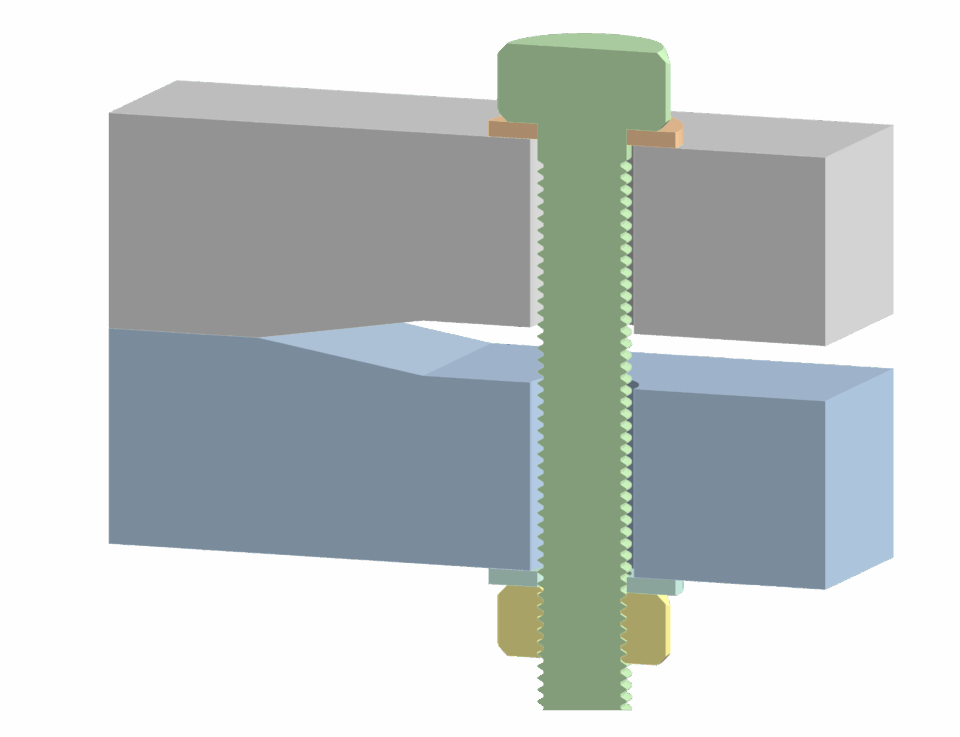

Screw calculation

Bolt verifications check the load-bearing capacity of prestressed and non-prestressed connections - depending on the type of load.

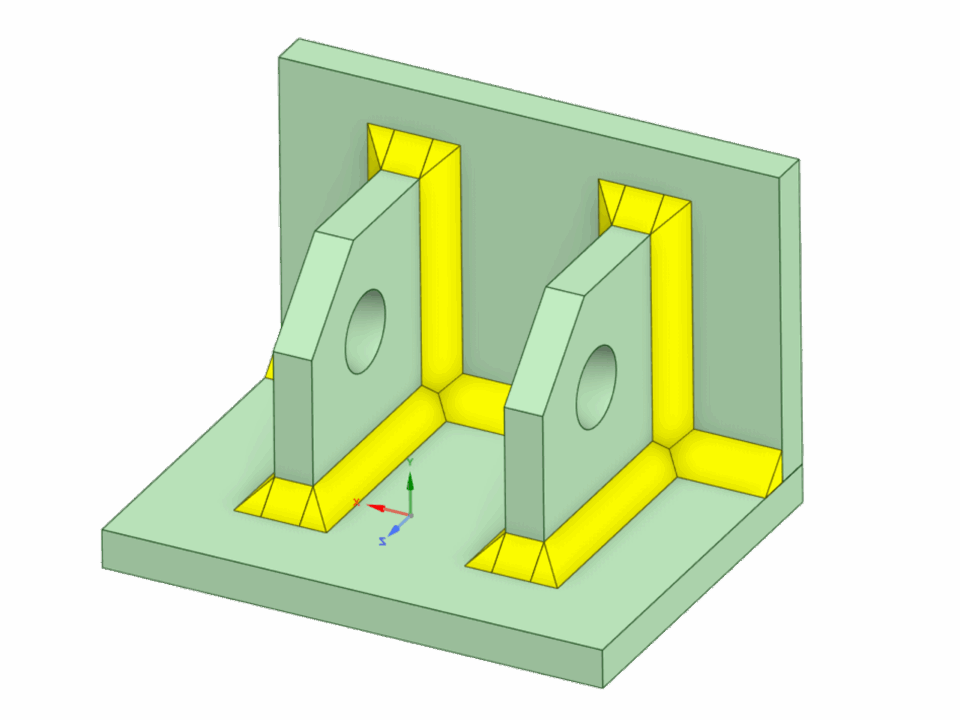

Weld seam calculation

Load-compliant design of weld seams for static and cyclic stresses.

Component optimization

Increased competitiveness through targeted and effective component optimization, such as the use of materials.

Fatigue strength verifications are essential when...

Your safety - our responsibility

it is known that loads are cyclical and that the structure is subject to high alternating stresses.

the cyclically loaded system or machine has weld seams in the force flow, as these are typically the weak points.

cracking or failure under real conditions of use should be prevented.

optimization potentials in material use or geometry are to be used in a targeted manner.

the component behavior under load is decisive - the focus is on stresses and deformations.

Advantages of a strength analysis of components

Measurable benefits. Verifiable quality.

With virtual simulations and sound calculations, we support you in developing products faster, safer and more economically. Our claim: reliable results that you can rely on.

Prevention of component failure

A fatigue strength verification can be used to ensure that the component can withstand the loads acting on it. This protects people and property.

Dimensioning of components

We determine the required dimensions and material properties to ensure a safe and resilient component. Especially with cyclical loads, it is difficult to estimate in advance.

Optimization of constructions

Particularly in the case of fatigue strength, the permissible number of cycles can be greatly increased through clever optimization, which improves the longevity of your components.

Our expertise for your project

We look forward to your inquiry!

As a specialized engineering office for FEA calculations and simulations, we offer you sound technical support in the preparation of standard-compliant strength verifications for your components in accordance with current regulations. We have particular expertise in the field of fatigue strength!

Do you have questions, need an assessment or want to get started right away?

We look forward to hearing from you – by phone, e-mail or in person.

Your contact person: Jonas Compart

elbcore engineers GmbH

Lerchenstraße 28a

22767 Hamburg

Do you have an exciting project?

Tell us about it.

Arrange a consultation now or send us a project inquiry.

Frequently asked questions (FAQ)

Quick answers. Clear solutions.

Here you will find answers to the most frequently asked questions about our services.

Which guidelines and standards can be used for fatigue analysis?

We carry out fatigue tests in accordance with the FKM guideline, VDI 2230, EN 1993 and other industry-specific standards. Customer-specific requirements or international standards (e.g. ASME, DNV) can also be taken into account. Please contact us if your standard is not listed!

In which phase is a fatigue analysis useful?

A fatigue analysis is particularly important for safety-relevant components that are subjected to dynamic loads over a longer period of time. It helps to identify critical points as early as the design phase and avoid costly modifications or failures later on.

Can existing components also be evaluated with regard to fatigue?

Yes, subsequent fatigue assessments are also possible – for example as part of service life analyses, conversion measures or when inspecting existing systems. We analyze the current condition and the remaining service life potential for you.

What is the difference between a static and a fatigue analysis?

While the static verification tests the strength under a single or constant load, the fatigue verification evaluates the behavior under cyclic, i.e. repeated stress – typically over millions of load cycles. It is essential for components that are exposed to vibrations, alternating loads or operating loads.

How much does a fatigue test cost and how long does it take?

This depends on the component, the complexity of the load and the information available. In many cases, however, we can make you a concrete offer after a brief preliminary discussion. Please feel free to arrange a free and non-binding consultation!

Do you still have questions? We are here for you.

Contact us now