Design of pressure vessels

Pressure vessels must be able to withstand high pressure, changing temperatures and complex operating conditions over the long term. We support you in the safe design, calculation and construction of pressure vessels. This gives you reliable results for planning, production and operation.

Strength calculation - pressure vessel

Safe & standard-compliant

A reliable design of pressure vessels forms the basis for the operational safety of your systems. We calculate tanks in typical plant construction, such as heat exchangers, silos, cyclones or other designs in accordance with relevant regulations, such as AD2000, DIN EN 13445 or the ASME Code.

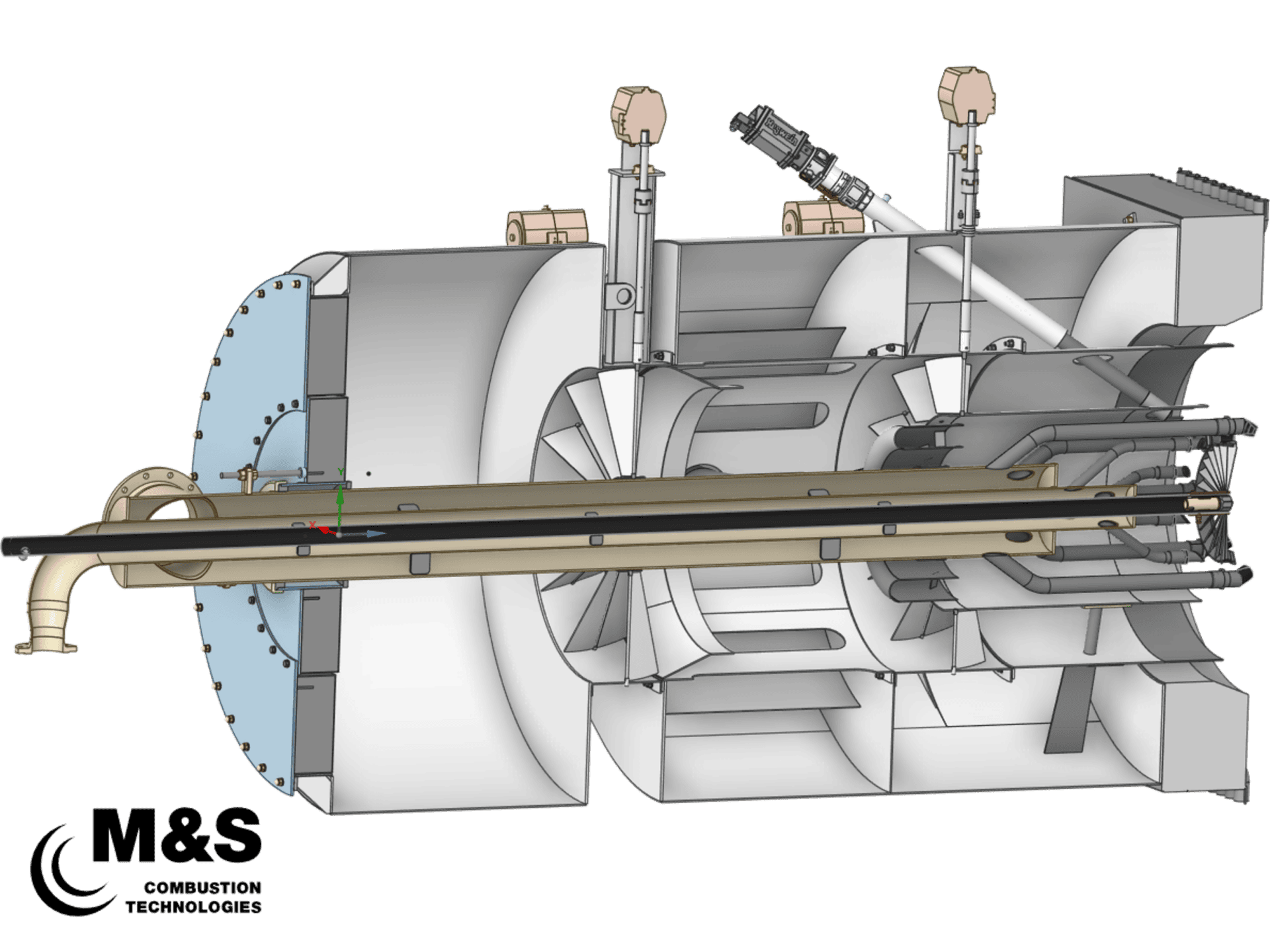

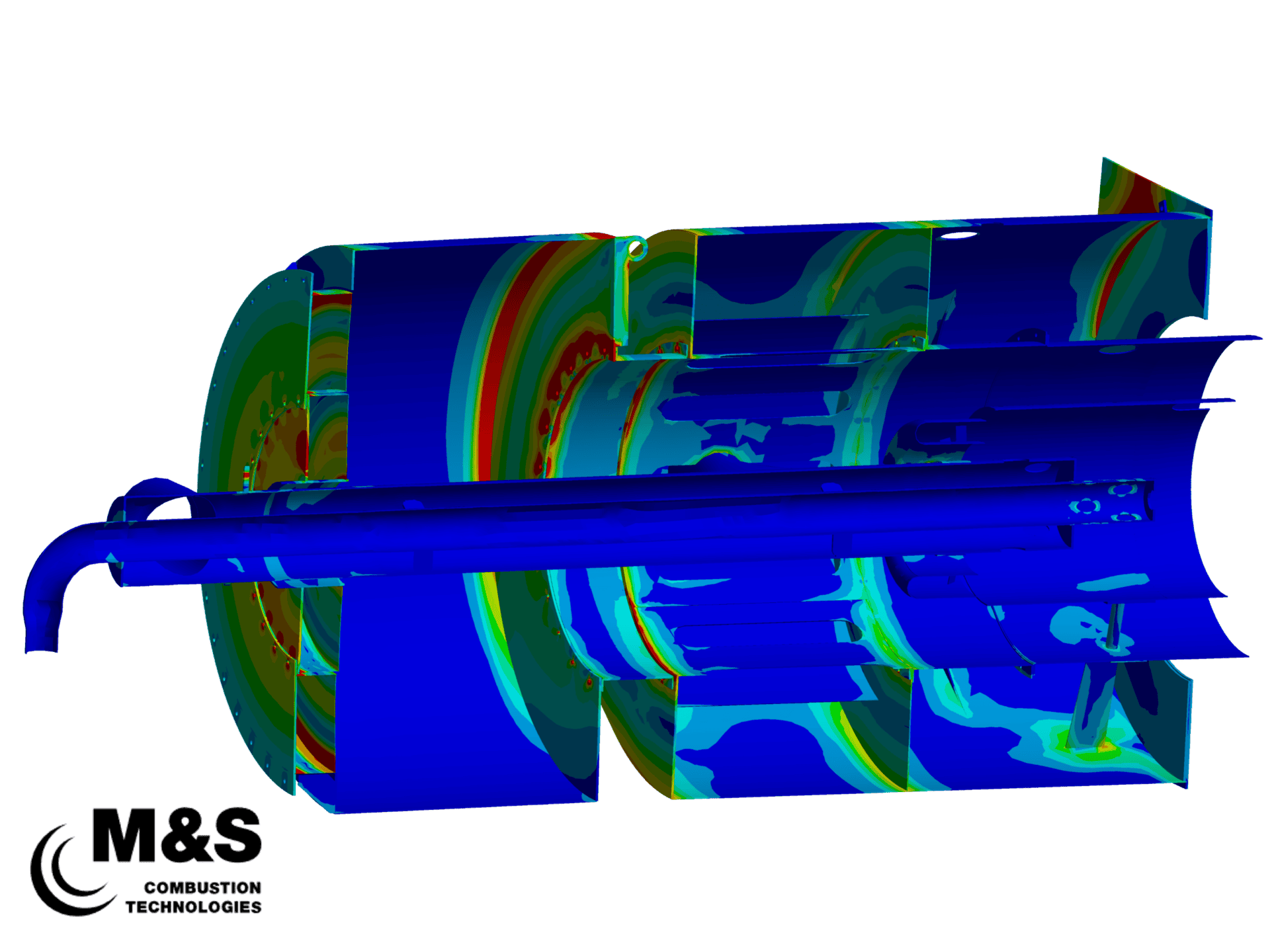

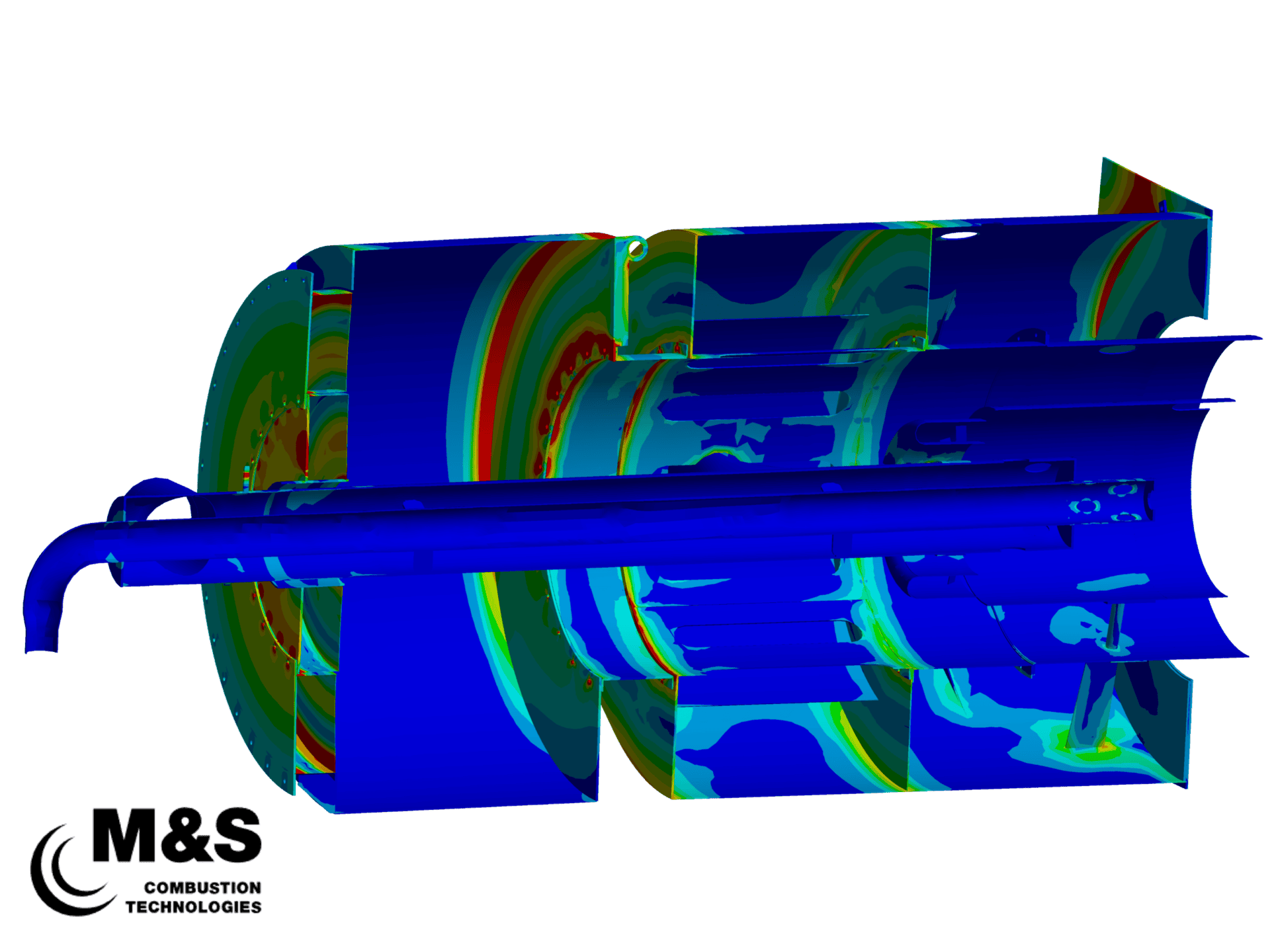

By combining classic methods with finite element analyses, stress peaks, critical zones and material reserves can be precisely identified. This enables reliable dimensioning and, where appropriate, targeted optimization of wall thicknesses.

Our range of services

Pressure vessel design & calculation

We create designs and strength verifications for pressure vessels of all types and support you with verifiable documents for production and approval. This includes analytical calculations, FEA analyses and the evaluation of thermal, static and dynamic loads.

Learn more

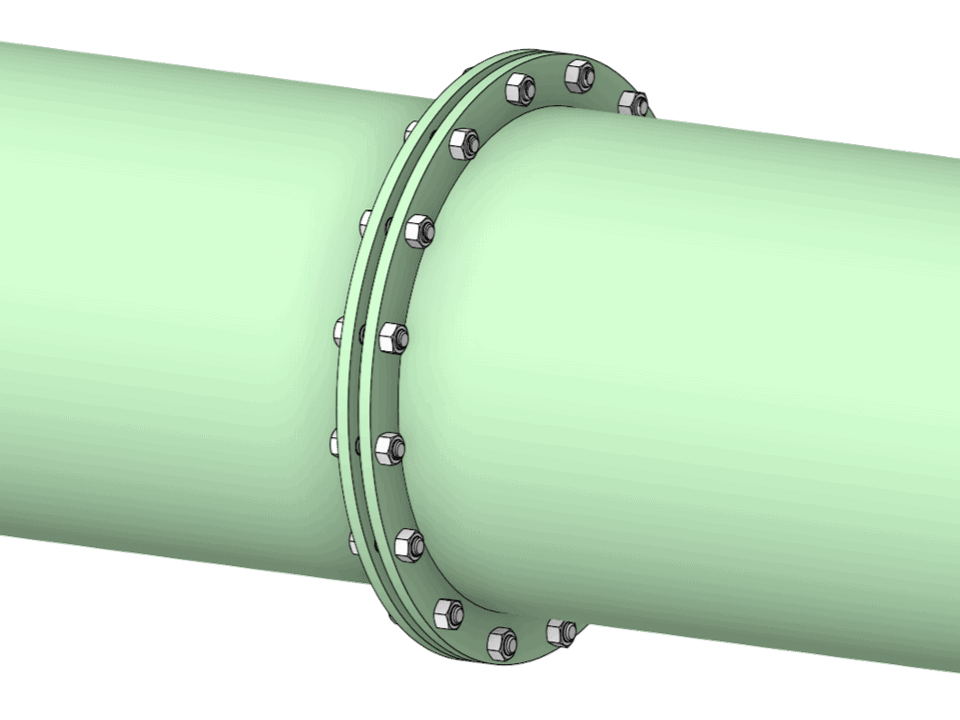

Learn moreScrew calculation

Bolt verifications check the load-bearing capacity of prestressed and non-prestressed connections - depending on the type of load.

Learn more

Learn moreWeld seam calculation

Load-compliant design of weld seams for static and cyclic stresses.

Component optimization

Increased competitiveness through targeted and effective component optimization, such as the use of materials.

A well-founded pressure vessel design is useful for you if...

Your challenges - our solutions

you want to ensure that your pressure vessels can withstand high pressure, temperature changes and complex process conditions over the long term.

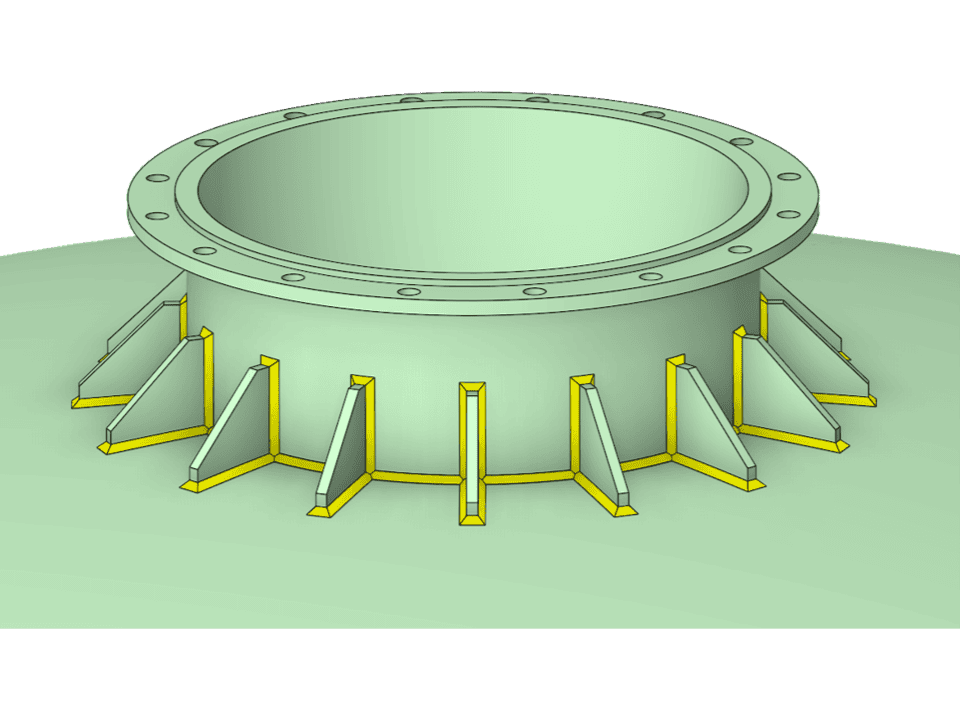

you want to have critical areas such as floors, nozzles, weld seams or installations reliably assessed in order to avoid cracks, leaks or material failure.

You have to precisely consider process parameters such as extreme temperatures, pressure fluctuations or corrosive media in order to determine suitable materials and wall thicknesses.

you want to compare variants or optimize wall thicknesses in order to achieve an economical and at the same time safe construction.

You need verifiable calculation reports and technical documentation to ensure smooth production, approval or TÜV acceptance.

Advantages of the pressure vessel design

Measurable benefits. Verifiable quality

With careful calculations, FEA analyses and reliable verifications, we create a reliable basis for the planning, design and operation of your pressure vessels.

Standard-compliant design

Calculations and design documents according to PED such as AD 2000, EN 13445 and ASME - including complete documentation.

Optimized material usage

We identify local loads and enable economical wall thicknesses without compromising safety.

Planning security

Reliable data for the design and approval of your pressure vessels at an early stage - for efficient processes and reliable project decisions.

Our expertise for your project

We look forward to your inquiry!

We accompany you through every step of the pressure vessel design process – from calculations and FEA analyses to verifiable design documents.

Do you have any questions, need an assessment or want to get started right away?

We look forward to hearing from you – by phone, email or in person.

Your contact person: Jonas Compart

elbcore engineers GmbH

Lerchenstraße 28a

22767 Hamburg

Strong across all sectors

Our services are used throughout the industry

Our engineering services are used in a wide range of industries - wherever safety, efficiency and technical precision are required.

Plant & tank construction

Electrical engineering

Mechanical engineering

Metal / steel construction

Shipbuilding

Special machine construction

Valve & pump technology

Your sector not listed?

Now contacted

Do you have an exciting project?

Tell us about it.

Arrange a consultation now or send us a project inquiry.

Frequently asked questions about pressure vessels

QUICK ANSWERS. CLEAR SOLUTIONS.

Here you will find answers to the most frequently asked questions about our services.

What types of pressure vessels can be calculated?

We support you in the design and calculation of a wide variety of pressure vessels and pressure equipment – including process vessels, storage tanks, autoclaves, heat exchangers, boilers, high-pressure vessels, hazardous goods tanks (e.g. in accordance with DIN EN 14025) and individual special designs.

We would also be happy to test your specific pressure device – send us a non-binding enquiry about your project.

Which materials can be considered?

We calculate pressure vessels and pressure equipment made from a wide range of technical materials, including

- Steels and stainless steels

- Carbon-manganese steels

- Low and high-alloy steels

- Aluminum

- Nickel-based alloys

We are happy to test other materials for pressure equipment individually on request.

Which standards are relevant for pressure vessels and pressure equipment?

Depending on the area of application and field of use, different sets of regulations for pressure vessels may be relevant, e.g:

- DGRL 2014/68/EU

- AD 2000

- EN 13445 (unfired pressure vessels)

- EN 13480 (piping)

- EN 12953 (shell boilers)

- DIN EN 14025 (hazardous goods tanks)

- ASME VIII (Div. 1 & 2)

We select the appropriate set of regulations for each project and take into account all relevant requirements for your pressure equipment.

Do you provide verifiable documentation for pressure vessels?

Yes, we prepare complete, verifiable documents for pressure vessels and pressure equipment that meet the requirements of TÜV and notified bodies.

These documents enable smooth production and approval of your pressure vessel.

Do you still have questions? We are here for you.

Contact us now