CFD calculation / flow simulation

With CFD simulations, we make the invisible visible – flowing media, pressure curves and temperature fields. Understand your process in detail and make well-founded decisions for development and optimization.

Planning reliability through digital CFD analyses

Flow made visible

We use CFD simulations to analyze the behavior of air, liquids or gases in your system – without any time-consuming tests or cost-intensive prototypes. Flow cannot be touched – but it can be visualized with CFD.

Whether cooling air in the housing, gas flows in a system or liquid distribution in the product: our simulations show you at an early stage where flow losses, temperature peaks or pressure problems occur – precisely, digitally and comprehensibly. This allows you to identify risks, improve your solutions in a targeted manner and make well-founded decisions – from concept to series production.

Our range of services

CFD services tailored to your requirements

With CFD simulations, we make the behavior of gases and liquids in and around your components visible - even before physical prototypes are created. For example, you can identify flow losses or unfavourable flow paths at an early stage, save valuable resources and optimize in a targeted manner.

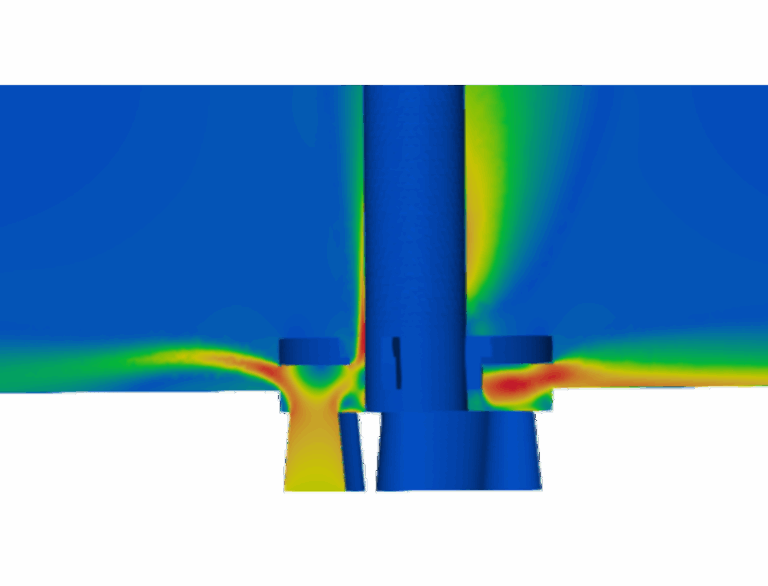

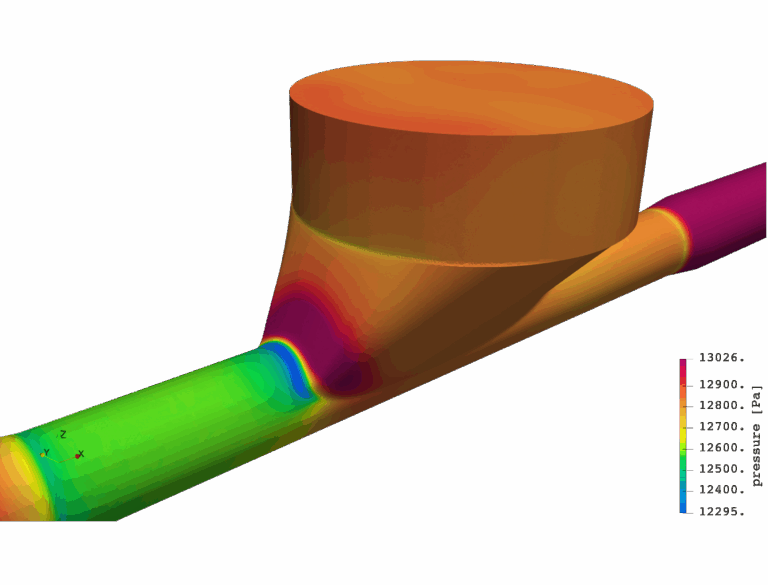

Speed distribution

We analyze flows in your systems - precisely, comprehensibly and with clear findings on dead zones and bypasses.

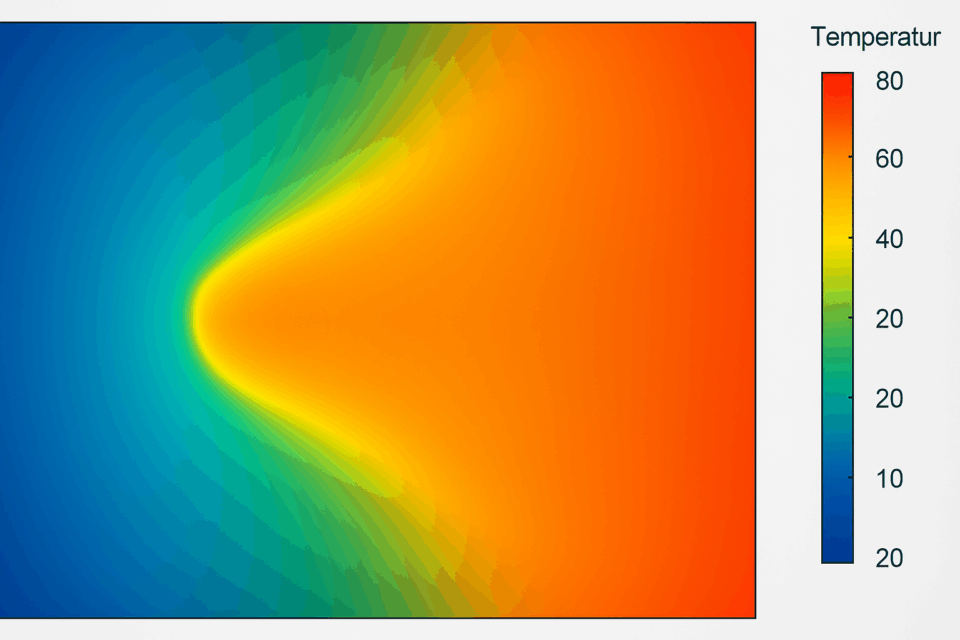

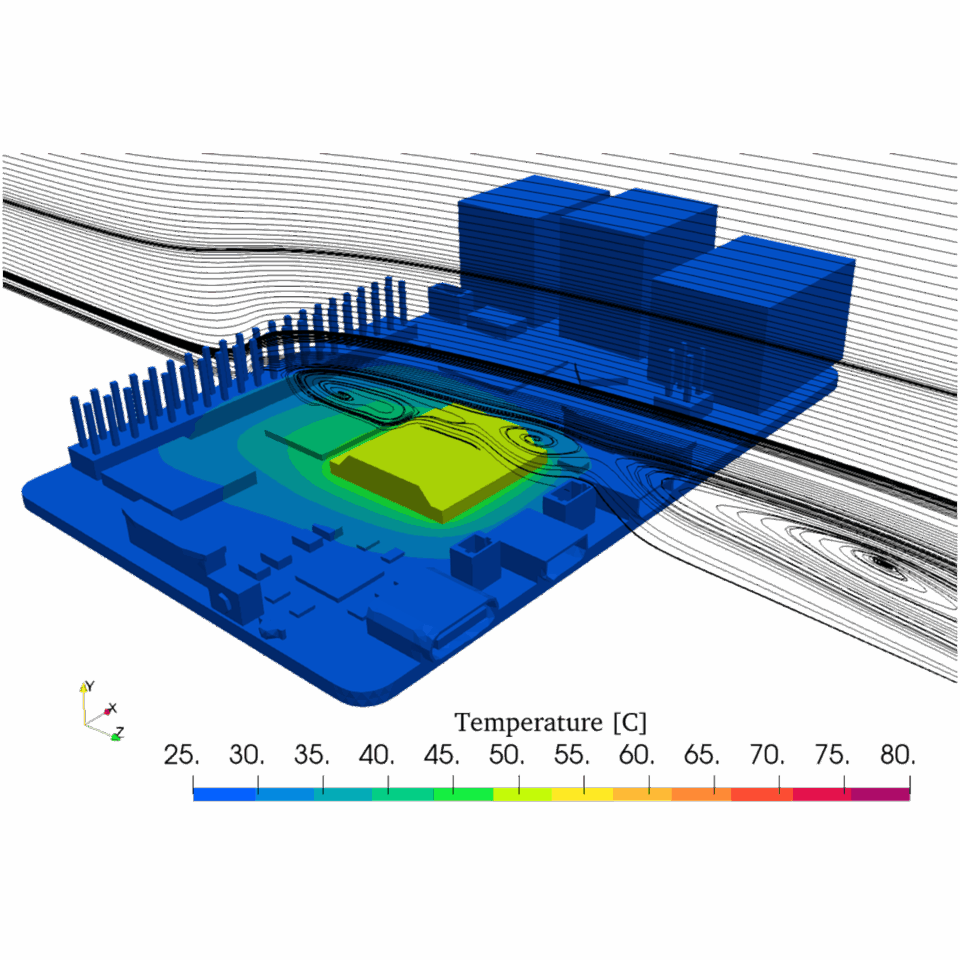

Temperature distribution

CFD simulations can be used to realistically map the heating and cooling behavior of their flows.

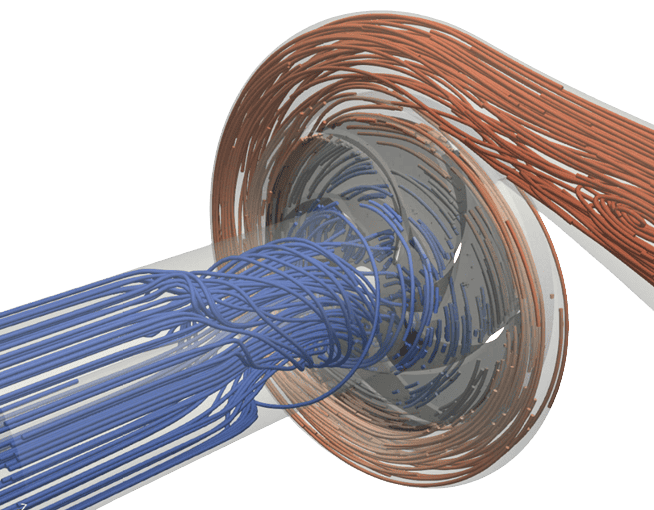

Mixing of fluids

Understand how to mix two media in your tanks and achieve faster homogenization.

CFD analyses are the right method when...

Your challenges - our solutions

You want to understand and optimize flow behavior, pressure losses or heat flows at an early stage - even before physical prototypes are built.

you want to identify critical areas in your products or systems - such as hotspots, dead zones or unwanted turbulence.

you want to model complex media flows realistically - e.g. for the design of ventilation, cooling, pumps or reactors.

you want to compare variants quickly - using simulation-based parameter studies instead of expensive individual tests.

you find real tests too complex, expensive or difficult to measure - e.g. in the case of internal flows or transient behavior.

Advantages of CFD simulations

Measurable benefits. Verifiable quality.

With virtual simulations and sound calculations, we support you in developing products faster, safer and more economically. Our claim: reliable results that you can rely on.

Analysis of product properties

Determine product properties, such as the flow around, flow and temperature distribution in components, during the planning stage. This allows you to identify the optimization potential of your product at an early stage and gives you peace of mind.

Cost-efficient prototypes

Flow simulations can be used to carry out calculations on virtual prototypes during development. This is cost-efficient and enables changes to be simulated quickly.

Quickly ready for series production

With the use of flow simulations and temperature calculations, tests can be reduced and series maturity can be achieved more quickly.

Our expertise for your project

We look forward to your inquiry!

As a specialist engineering office for CFD simulations, we offer you sound technical support in the development and optimization of complex components. Our team of experienced engineers will think deeply about your tasks – solution-oriented, comprehensible and practical.

Do you have questions, need an assessment or want to get started right away?

We look forward to hearing from you – by phone, e-mail or in person.

Your contact person: Jonas Compart

elbcore engineers GmbH

Lerchenstraße 28a

22767 Hamburg

Strong across all sectors

Our services are used throughout the industry

Our engineering services are used in a wide range of industries - wherever safety, efficiency and technical precision are required.

Building technology

Chemical & process industry

Automotive industry

Aerospace

Energy & power plant technology

Pharmaceuticals & Biotechnology

Electronics & semiconductor indistrue

Your sector not listed?

Now contacted

Do you have an exciting project?

Tell us about it.

Arrange a consultation now or send us a project inquiry.

Frequently asked questions (FAQ)

Quick answers. Clear solutions.

Here you will find answers to the most frequently asked questions about our services.

What information do we need to provide in order to start a project?

For an efficient CFD simulation, we need your CAD data, boundary conditions (e.g. temperatures, volume flows) and information about your objective – e.g. optimization, error analysis or feasibility study. Simply send us your data using our inquiry form – we will check what is possible free of charge.

How long does a typical CFD simulation take?

The time required depends heavily on the complexity of the geometry, the problem and the computational effort. Initial results for simple cases are often possible within a few days – complex projects can take several weeks. Let us talk about your project – click here for a free consultation.

Do you also provide support in interpreting and optimizing results?

Absolutely. We don’t just deliver pretty pictures, but clear recommendations – whether for flow control, temperature distribution or geometry adaptation.Use our experience to turn simulation results into real competitive advantages.

What software do you use - and how reliable are the results?

We work with validated tools such as ANSYS Fluent or Open Foam and ensure quality through internal standards, benchmarks and – if required – comparison with measurement data. Feel free to ask us about reference projects or sample analyses from your industry.

Do CFD simulations also make economic sense for small projects or medium-sized companies?

Yes, thanks to lean modeling and targeted questions, CFD analyses are often cheaper than lengthy test runs or prototypes. Talk to us about your idea – together we will find a realistic and cost-effective solution.